We Build for OEM Standards, Not Market Shortcuts

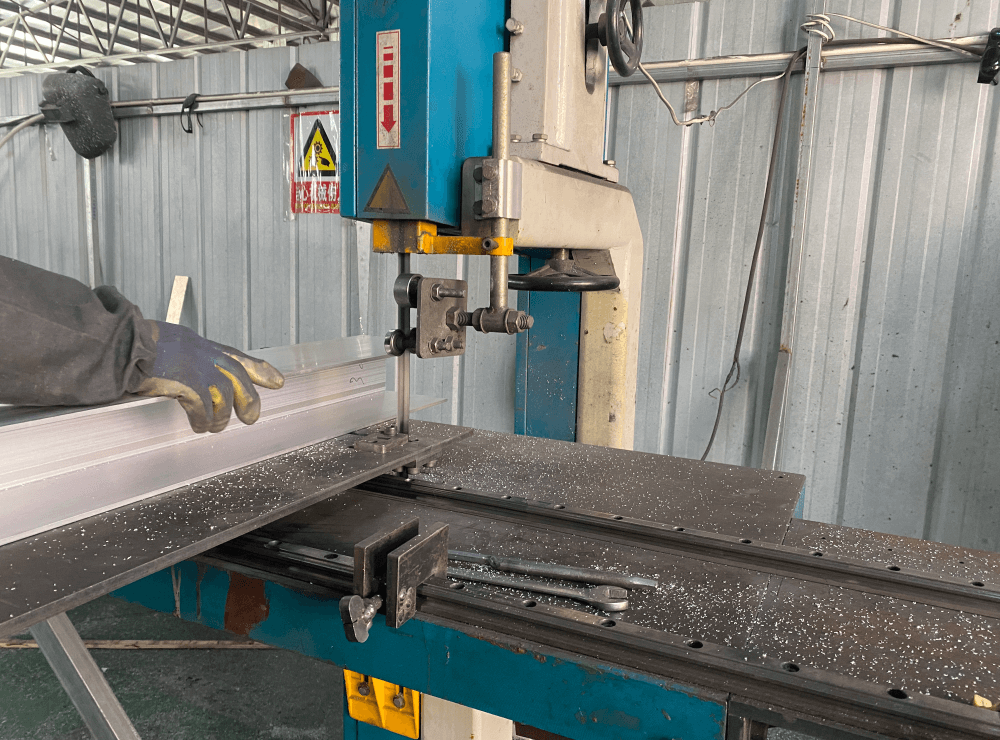

Heavy-duty truck accessories aren't fashion items—they protect vehicles and drivers in real working conditions. That's why we've invested years building production systems that deliver consistent quality at scale.

We serve OEM clients and established brands because we understand their pain points: tight delivery windows, strict spec requirements, and zero tolerance for batch inconsistency. Our factory was designed around these realities.