Heavy-Duty Truck Accessories for OEM & Fleet Applications

Structural aluminum and steel components engineered specifically for North American heavy-duty trucks. Precision-manufactured accessories that integrate seamlessly with your fleet operations.

Request Accessories OEM QuoteStructural Accessories Product Family

Four specialized product lines designed to meet the demanding requirements of heavy-duty trucking. Each component is engineered for structural integrity and long-term reliability.

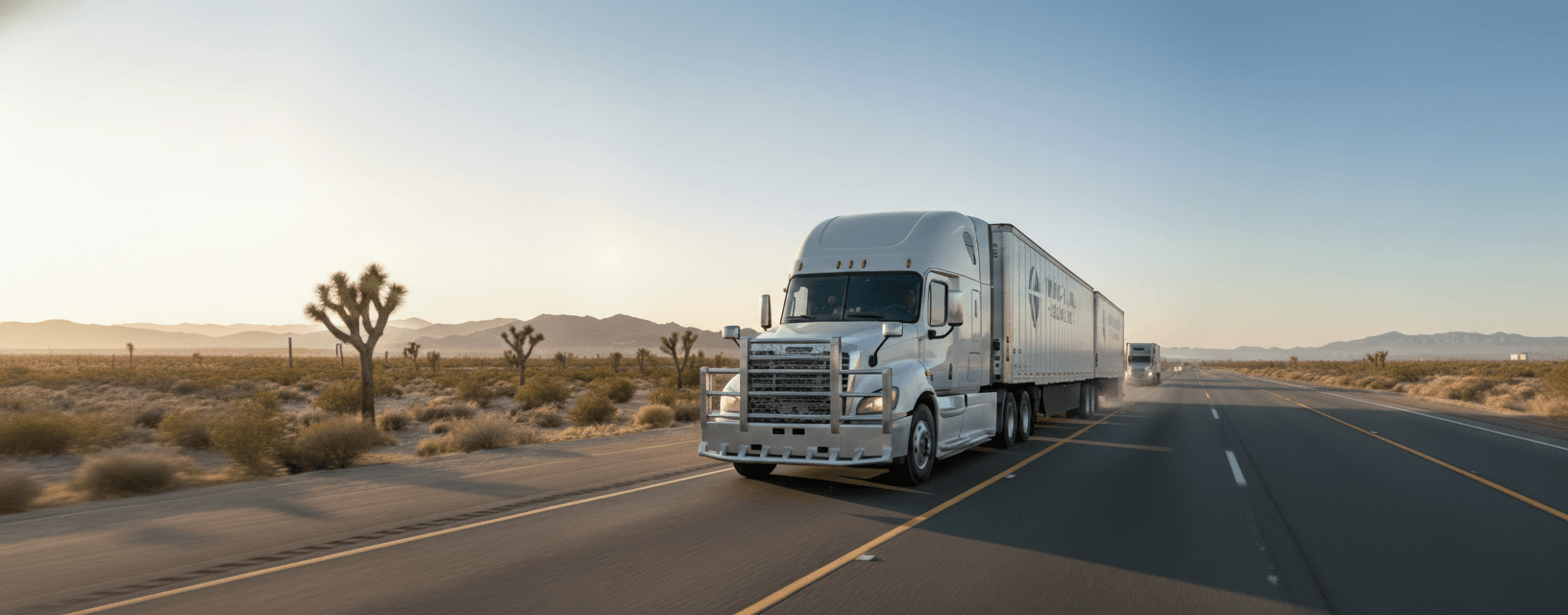

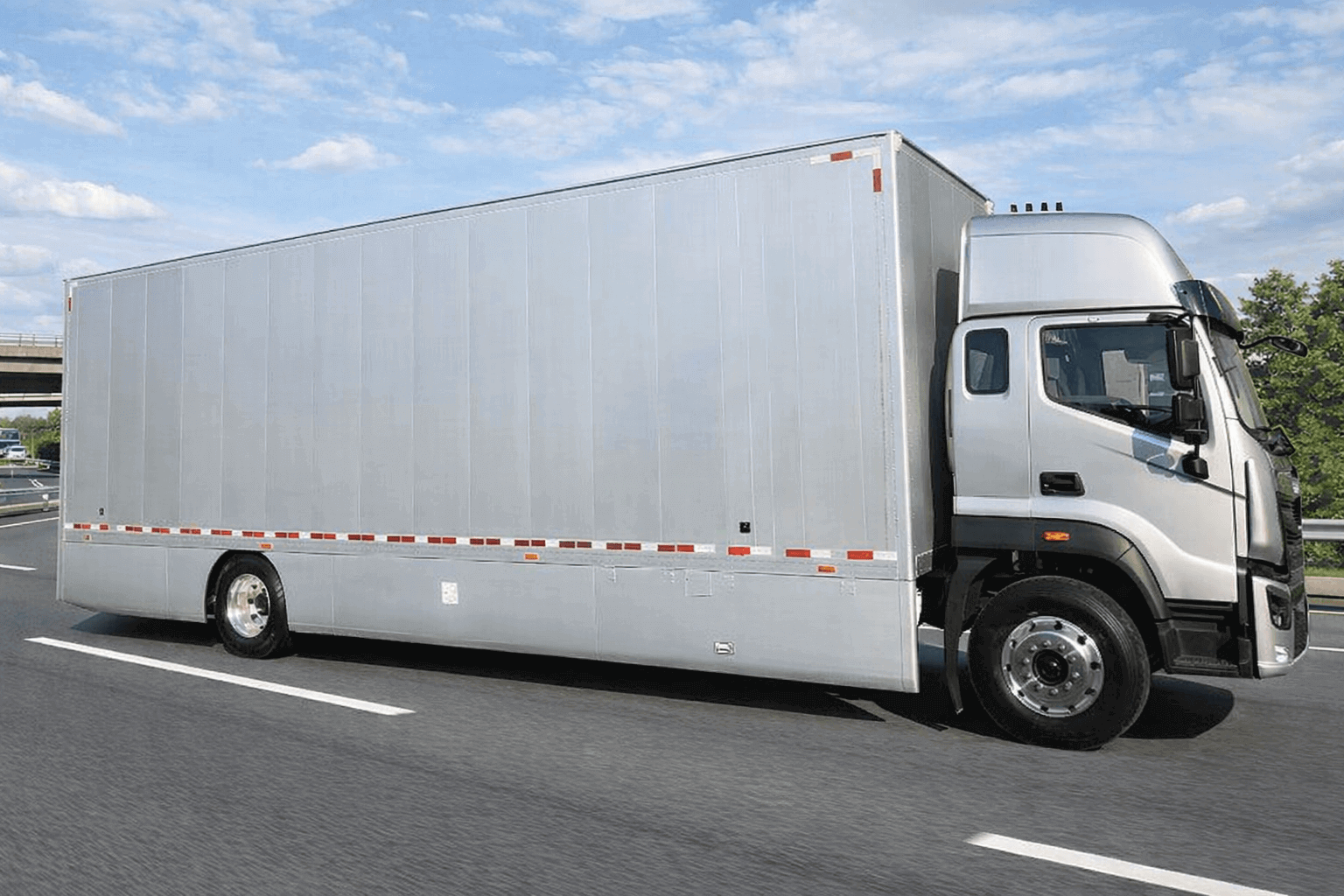

Truck Body

Complete aluminum structural body systems engineered for maximum payload capacity while maintaining superior durability.

Heavy-duty trucks & trailers

View Details

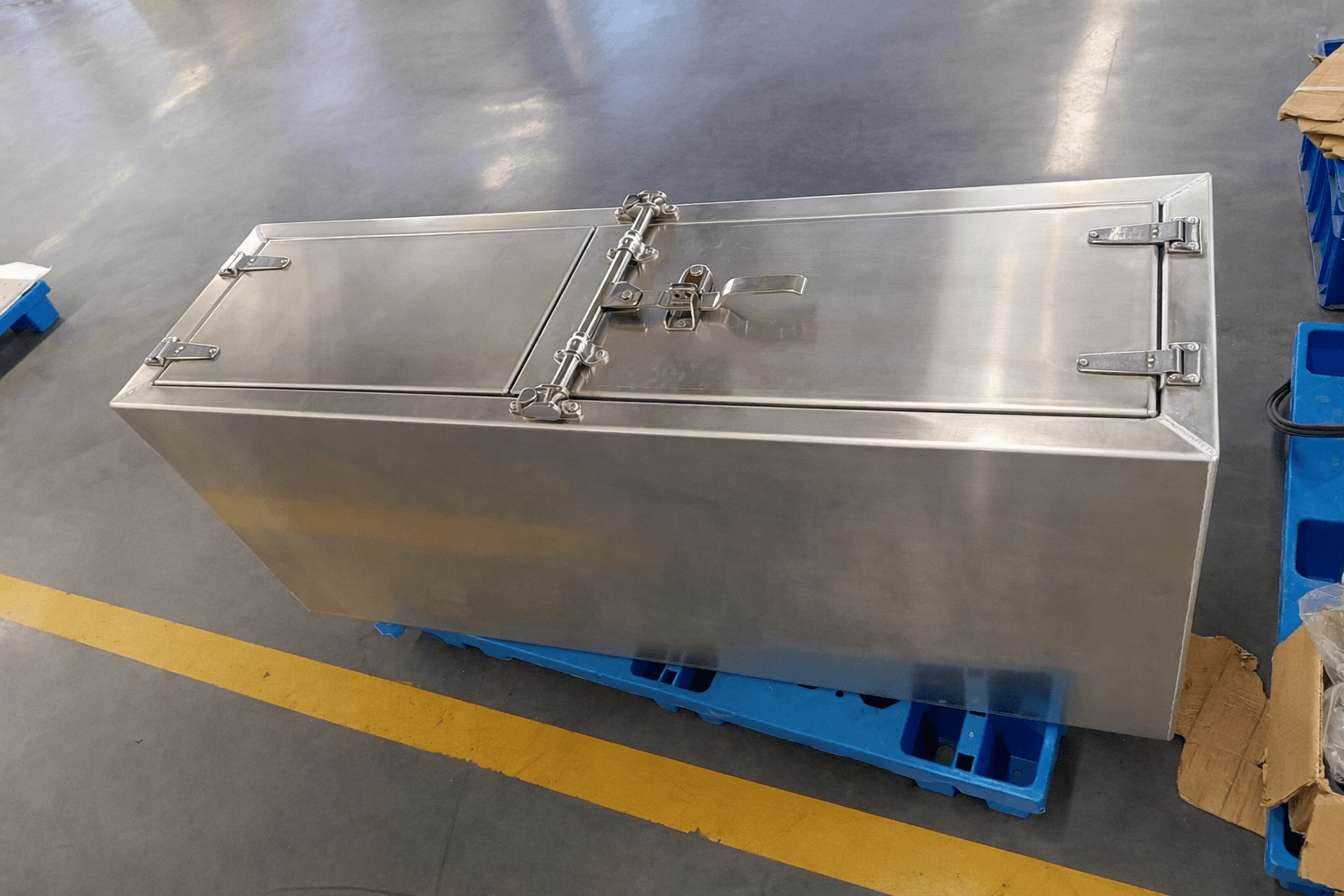

Tool Box

Heavy-duty storage solutions built to withstand harsh conditions with secure locking mechanisms and weather-resistant seals.

Aluminum / steel options

View Details

Chain Hangers

Engineered chain storage systems with frame-mounted design for secure load management and quick deployment access.

Frame-mounted design

View Details

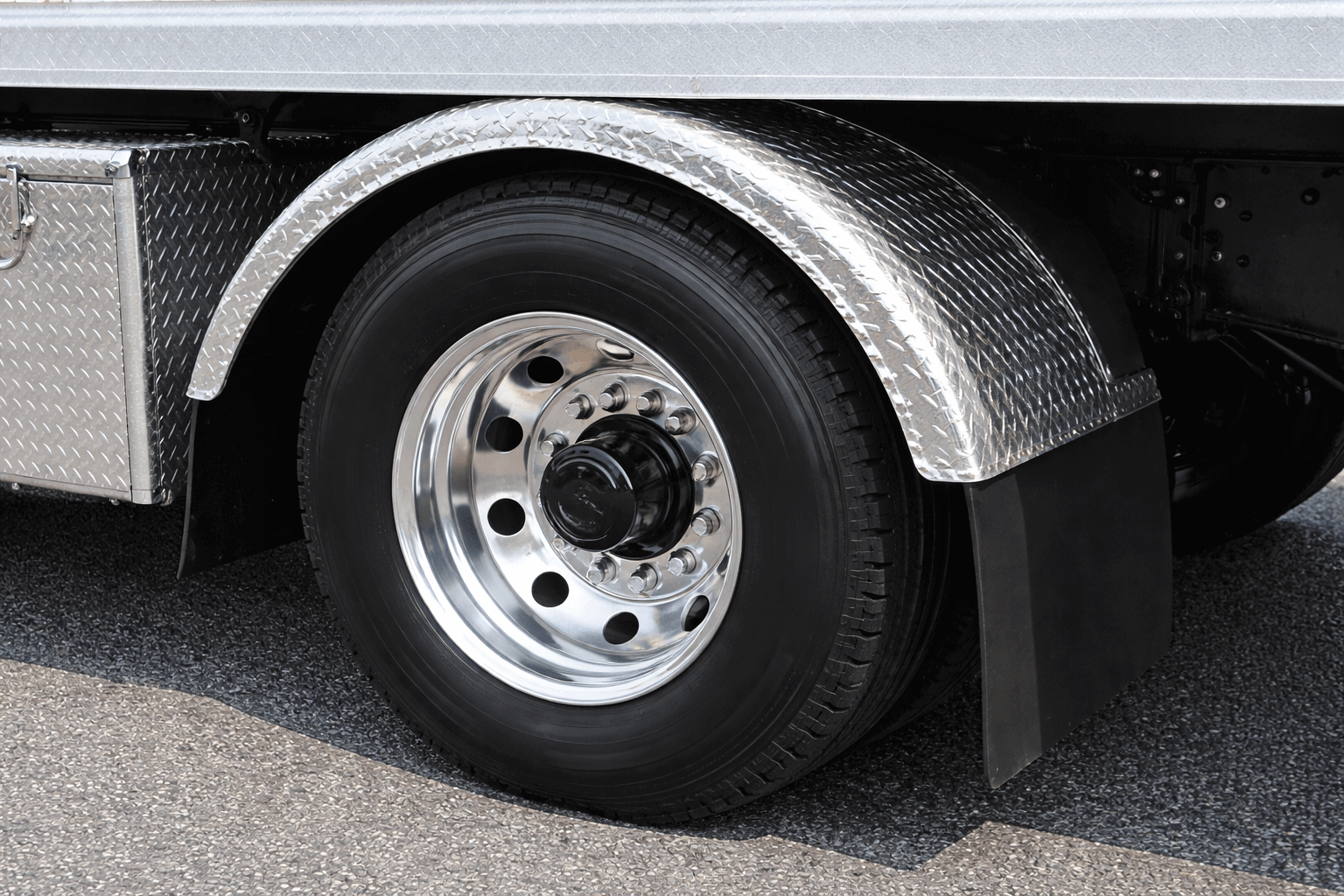

Fenders

Heavy-duty wheel protection components built to resist road debris impact and provide years of reliable service.

Steel / aluminum structures

View DetailsNeed a custom configuration for your specific application?

Discuss Your RequirementsThe Cost of Accessory Failure

Substandard accessories don't just fail—they create cascading problems that impact your operations, safety, and bottom line. Understanding these risks helps you make informed sourcing decisions.

Truck Body

- Structural deformation under load

- Mounting point failure

Tool Box

- Corrosion & seal degradation

- Door misalignment issues

Chain Hangers

- Weld joint failure

- Load drop hazards

Fenders

- Cracking under stress

- Vibration fatigue damage

Accessory failures disrupt fleet operations just as severely as bumper failures. Every component in our product line is engineered to eliminate these risks from your supply chain.

Eliminate accessory failure risks from your fleet operations.

Get Reliable ComponentsWhat We Build vs. What We Don't

We specialize in structural OEM components—not aftermarket accessories. Understanding this distinction ensures you're working with the right manufacturing partner for your needs.

What We Manufacture

- OEM-spec structural components for heavy-duty trucks

- Load-bearing accessories with engineered specifications

- Bulk orders for fleet programs and distributors

- Custom ODM projects with documented specifications

Not Our Scope

- Consumer aftermarket accessories and cosmetic parts

- Single-unit retail orders or small quantities

- Generic universal-fit replacement parts

- Light-duty passenger vehicle accessories

Ready to work with a focused OEM manufacturing partner?

Start OEM DiscussionOne Engineering System, Four Product Lines

Every accessory we manufacture shares the same engineering DNA. Our unified approach to structural design ensures consistent quality whether you're ordering truck bodies or chain hangers.

Structural Load Path Design

Every component is engineered with optimized load paths that distribute stress evenly across the structure, preventing failure points under heavy operational loads.

Mounting Accuracy

Precision jigs and CMM verification ensure every mounting point aligns perfectly with vehicle specifications, enabling seamless installation every time.

Vibration & Fatigue Testing

Components undergo rigorous vibration analysis and fatigue testing protocols to ensure they withstand the harsh conditions of commercial trucking operations.

Corrosion Protection

Multi-layer coating systems and material selection optimized for long-term corrosion resistance in demanding North American climate conditions.

Integrated Manufacturing Excellence

Our unified engineering approach means you get the same quality standards across all product lines. Whether ordering truck bodies, tool boxes, chain hangers, or fenders, every component benefits from our proven manufacturing system.

See how our engineering capabilities can support your accessory program.

Schedule Technical ConsultationProduct-Specific OEM/ODM Options

Every product line offers comprehensive customization to meet your exact specifications. From dimensional modifications to material selection, we adapt our manufacturing to your requirements.

Truck Body

Tool Box

Chain Hangers

Fenders

Have specific customization requirements? Let's discuss your project specifications.

Submit Custom SpecsBatch Consistency & Quality Control

Our manufacturing processes are designed to deliver identical quality from your first sample to your thousandth production unit. Consistency you can count on, order after order.

Sample = Production

What you approve in samples is exactly what you receive in bulk. Our production samples come from the same tooling and processes used for full-scale manufacturing.

Locked Mounting Points

Precision jigs and fixtures lock in critical dimensions. Every mounting hole, every bracket position is verified to match your vehicle specifications exactly.

Repeat Order Accuracy

Reorders ship with identical specifications to your original order. Our documented process control ensures year-over-year consistency for ongoing programs.

Long-Term Supply

Built for multi-year partnerships. Dedicated production capacity and documented tooling ensure we can support your accessory program for the long term.

Experience production quality that scales with your business needs.

Request Quality DocumentationHeavy-Duty Packaging & Delivery

Our export packaging is engineered specifically for heavy structural components. Every shipment arrives in the same condition it left our facility—ready for immediate installation.

Pallet-Fixed Components

Heavy components are securely strapped to reinforced pallets, preventing movement and ensuring stability throughout international transit.

Anti-Deformation Protection

Custom bracing and support structures protect precise geometries from shipping stress. Your components maintain their engineered dimensions.

Surface Damage Prevention

Protective wrapping and edge guards safeguard finished surfaces. Powder coating and paint finishes arrive scratch-free and installation-ready.

Container Optimization

Strategic loading plans maximize container utilization while maintaining product protection. Lower per-unit shipping costs without compromising quality.

Learn how our logistics expertise ensures damage-free delivery to your facility.

Discuss Shipping RequirementsWho Our Accessories Are Built For

Our structural accessories serve specific market segments where quality, consistency, and OEM-level engineering are non-negotiable requirements.

Truck Accessory Brands

Established brands seeking reliable OEM manufacturing for their product lines with consistent quality and competitive pricing.

- Private label options

- Product development support

Fleet Operators

Large fleet managers requiring standardized accessories across their vehicle inventory with long-term supply agreements.

- Volume pricing programs

- Scheduled delivery options

Distributors & Wholesalers

Regional and national distributors looking for quality accessory sources with competitive margins and reliable inventory support.

- Bulk order discounts

- Drop-ship capabilities

Body Builders & Trailer Manufacturers

Commercial vehicle builders integrating structural accessories into their production lines with just-in-time delivery needs.

- JIT delivery programs

- Integration engineering

Find out how we can support your specific business requirements.

Discuss Partnership OptionsStart Your Accessories OEM Partnership

Many of our long-term bumper programs began with a single accessory project. Let us demonstrate our manufacturing capabilities with your next tool box, truck body, or chain hanger order.

Request Accessories OEM QuoteMany long-term bumper programs start with a single accessory project.