-

Extreme Animal Mass

Wildlife impacts often exceed 1,000 lbs, generating collision forces that overwhelm standard bumper designs.

-

Critical System Exposure

Impact height aligns directly with cooling systems, steering components, and radiator assemblies.

-

Extended Recovery Times

Recovery in remote locations is measured in days, not hours—multiplying the cost of each incident.

-

Compounding Lifecycle Costs

Repeated incidents without proper protection exponentially increase total cost of ownership.

Front-End Protection Challenges for Logging & Northern Fleet Trucks

Logging and northern fleet operations face some of the highest-impact collision risks in North America. Standard front-end components are not designed for repeated animal strikes or remote recovery scenarios.

Why Logging & Northern Fleets Face Unique Front-End Risks

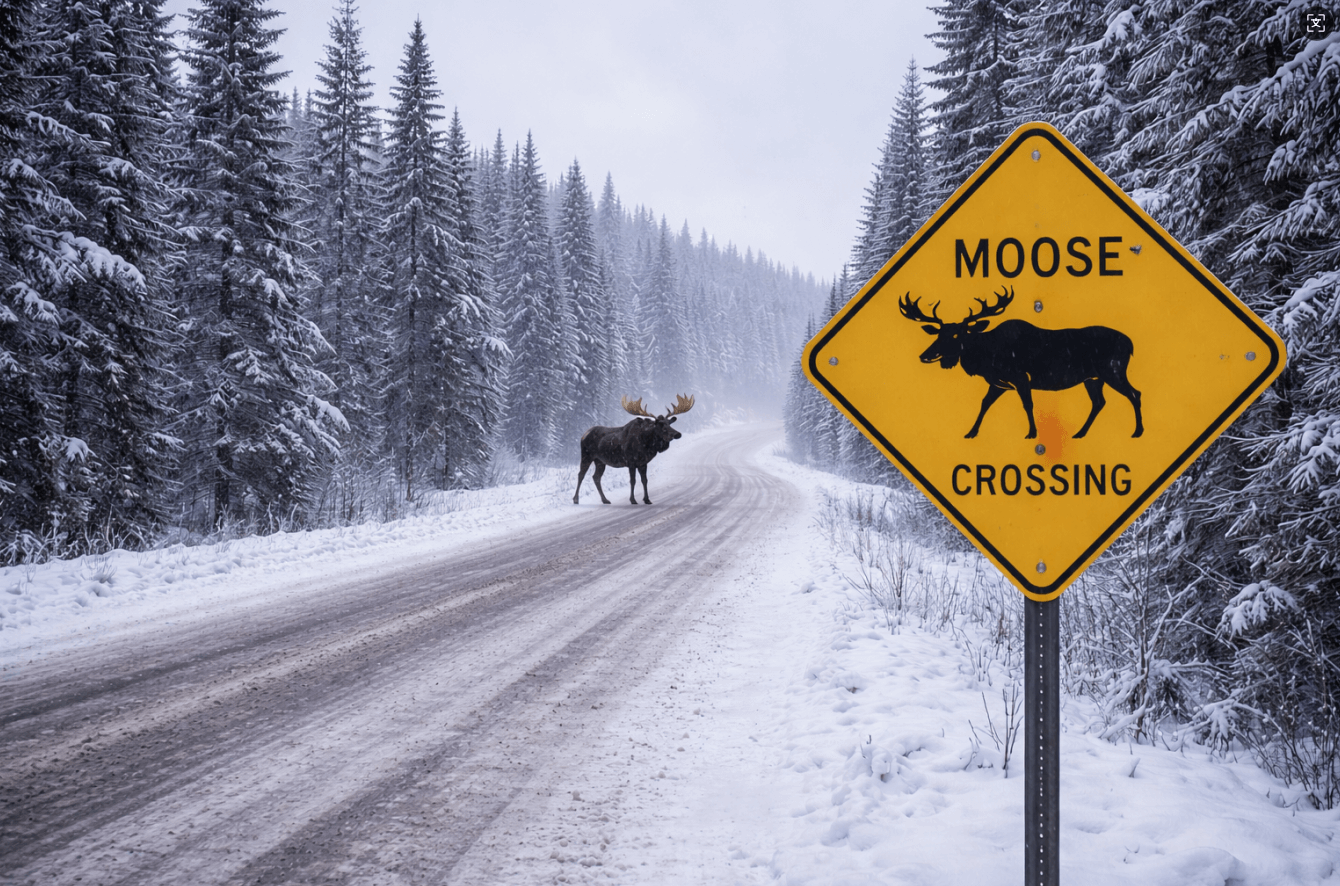

Logging and northern fleets operate in environments where wildlife collisions are not rare events—they are an expected operational risk that demands purpose-built protection solutions.

Large animals such as moose and elk strike at radiator and hood height, transferring massive impact forces directly into critical vehicle systems. In remote regions, even a single front-end failure can result in extended downtime due to towing delays, limited repair access, and lost productivity.

Understanding these risks is the first step toward building a reliable protection strategy.

Discuss Your Route ConditionsWhy Factory and Light-Duty Guards Fall Short

Factory-installed bumpers are primarily designed to meet regulatory and aerodynamic requirements—not to absorb or redistribute high-energy wildlife impacts. Light-duty aftermarket guards often prioritize appearance over structural load paths.

Energy Concentration at Mounting Points

Impact forces concentrate at weak mounting brackets instead of being distributed across the frame structure, leading to bracket failure and component damage.

Direct Frame Rail Deformation

Without proper load transfer engineering, impact energy transmits directly into frame rails, causing structural damage that compromises vehicle integrity.

Guard Collapse Into Components

Lightweight guards designed for aesthetics collapse under high-mass impacts, pushing into radiators and steering systems they were meant to protect.

Single-Impact Design Limits

Most guards are engineered for one-time impact absorption, requiring full replacement after a single collision event—impractical for high-risk routes.

The Core Engineering Issue

The issue is not material strength alone—it's how impact forces are managed and transferred through the protection system. Without engineered load paths, even strong materials fail to protect critical vehicle systems.

Ready to move beyond inadequate protection solutions?

Explore Engineering-Grade OptionsEngineering a Structural Front-End Protection System

Effective protection for logging and northern fleets requires a system-level approach, not a single component. Our engineering strategy addresses the complete impact energy pathway.

Primary Impact Absorption

Structural aluminum bumper engineered to absorb and distribute initial collision energy across a wider surface area.

Controlled Load Transfer

Engineered mounting system directs forces into frame-mounted points, protecting vulnerable components from direct impact stress.

Secondary System Protection

Reinforced grille guard provides additional protection layer for cooling systems and front-end components.

Repeated Service Validation

Design validated for repeated impacts over the vehicle lifecycle, not just single-event survival.

Learn how this engineering approach applies to your specific fleet configuration.

Request Technical ConsultationRecommended Protection Configuration for Logging Fleets

A complete protection system combines primary, secondary, and application-specific components—each engineered to work together for maximum fleet survivability.

Aluminum Moose Bumper

Heavy-duty structural aluminum construction delivers superior impact resistance while optimizing weight for improved fuel efficiency and payload capacity.

- Optimized strength-to-weight ratio

- Corrosion-resistant construction

- Platform-specific fitment

Reinforced Grille Guard

Stainless steel grille guard provides additional protection for cooling systems and front-end components, engineered to complement bumper performance.

- Cooling system protection

- Integrated mounting design

- Debris deflection capability

Fender & Accessory Protection

Application-dependent coverage options for debris and side impact risks—customized to your specific route conditions and operational requirements.

- Side impact mitigation

- Road debris protection

- Route-specific customization

Configuration Note: Final configurations are adapted to vehicle platform, route conditions, and fleet standards. Our engineering team works with you to determine the optimal protection package for your specific operational requirements.

Ready to configure the right protection package for your logging fleet?

Get Custom ConfigurationProven in Real Fleet Operations

Our protection systems have been validated through years of real-world deployment across demanding logging and northern fleet operations.

Midwest Logging Fleet Reduced Moose Collision Downtime

A major logging operation in the upper Midwest implemented our structural bumper system across their fleet. After 18 months of operation, they documented significant reductions in collision-related vehicle downtime and repair costs.

View Case StudyNorthern Fleet Improved Front-End Survivability Across Multiple Routes

A northern transportation company standardized our protection configuration across their long-haul fleet operating on high-risk wildlife corridors. The integrated protection system has maintained structural integrity through multiple impact events.

View Case StudyNo proprietary drawings. No sensitive operational details. Just validated outcomes from real fleet deployments.

Want to see how our solutions perform in operations similar to yours?

Request Detailed Case StudiesBuilt for Fleet Programs, Not One-Off Installs

We operate as an engineering-grade manufacturing partner, not a retail seller. Our capabilities are designed to support long-term fleet protection programs with consistent quality and reliable supply.

OEM / ODM Manufacturing

Full original equipment and design manufacturing capabilities enable custom solutions tailored to your specific fleet requirements and brand standards.

Platform-Specific Fitment

Every product is validated for precise vehicle platform fitment using dedicated jigs and CMM verification to ensure consistent bolt-on installation.

Consistent Batch Production

Rigorous quality control across production batches ensures every unit meets the same standards—critical for fleet-wide standardization and maintenance planning.

Long-Term Supply Support

Dedicated production capacity and inventory management support fleet standardization programs with reliable supply continuity and responsive reorder fulfillment.

Looking for a manufacturing partner who understands fleet-scale requirements?

Discuss Partnership OpportunitiesPlanning Protection for Logging or Northern Routes?

Our engineering team is ready to review your specific application requirements, route conditions, and fleet standards to develop a protection configuration that addresses your operational challenges.