Moose Collision Downtime Reduction

Reducing operational uncertainty for long-haul fleets operating in high-frequency wildlife collision environments through consistent, repairable protection systems.

Explore Long-Haul Fleet ApplicationsOperating Environment

Where This Challenge Exists

Understanding the operational context helps fleet managers recognize whether their operations face similar risks and could benefit from optimized protection strategies.

North American Corridors

Long-haul operations spanning highways, interstates, and rural routes across the U.S. and Canada where large wildlife populations are prevalent.

Class 8 Heavy-Duty Trucks

High-mileage vehicles operating continuously under demanding schedules where any unplanned downtime directly impacts delivery commitments and revenue.

Wildlife Risk Zones

Routes through moose, deer, and elk habitats where animal crossings are not occasional hazards but predictable, seasonal operational risks.

Continuous Operations

Fleets running year-round schedules where vehicle availability and maintenance predictability are critical to maintaining service levels and profitability.

Operating in similar high-risk environments? Explore related applications.

View Logging & Northern FleetsThe Real Problem

Wildlife Collisions Create Operational Disruptions, Not Just Accidents

Most animal strikes don't result in catastrophic damage. They result in functional impairment—damaged cooling systems, broken lighting assemblies, compromised front-end structures. The truck still exists, but it can't operate until repairs are completed.

The critical question isn't whether a collision will happen—it's what happens to your operations after it does. Unpredictable repair timelines disrupt schedules, strain resources, and create cascading delays.

- Cooling system damage forces immediate vehicle shutdown regardless of delivery urgency

- Lighting failures create compliance issues that prevent continued operation

- Structural damage to mounting points complicates repair assessment and parts sourcing

Operational Impact

Downtime creates ripple effects across scheduling, customer commitments, and maintenance budgets

Ready to understand how protection design affects repair outcomes?

Explore Moose Bumper SolutionsCurrent Challenges

Why "Having Protection" Doesn't Solve the Problem

Installing aftermarket bumpers addresses visibility, but inconsistent manufacturing creates unpredictable repair scenarios that undermine operational planning.

Inconsistent Manufacturing Quality

Many aftermarket bumpers aren't engineered for repeated high-frequency impact scenarios. Variations between production batches mean mounting interfaces and structural performance differ from unit to unit.

Variable Repair Outcomes

After an impact, some trucks get back on the road quickly while others require extensive teardowns. Without consistent structural behavior, maintenance teams can't accurately estimate repair timelines or parts requirements.

Parts Sourcing Delays

When bumper components aren't standardized across a fleet, each repair becomes a custom procurement exercise. Lead times for replacement parts add days or weeks to what should be routine maintenance.

The Hidden Cost of Inconsistency

Fleet managers need repair outcomes they can plan around—not surprises that disrupt operations and budgets. Consistent manufacturing directly translates to predictable maintenance.

What Matters Most

What Fleet Managers Actually Need to Solve

Professional fleet operators don't ask for indestructible equipment. They ask for equipment that performs predictably and supports efficient operations over the long term.

Not the Priority

- Completely preventing all wildlife collisions (impossible in reality)

- Bumpers that survive impacts without any damage

- One-time purchase decisions without lifecycle consideration

The Real Requirements

- Controlled, predictable repair processes after impacts occur

- Consistent behavior across all fleet vehicles for standardized maintenance

- Reliable parts availability and interchange compatibility

- Long-term supplier stability for ongoing fleet programs

Aligns with how you evaluate equipment decisions? Let's discuss your fleet requirements.

Talk to Our Engineering Team

Build-to-Print

Precision OEM Manufacturing

Our Role

Manufacturing Execution, Not Design Leadership

We execute your specifications with precision. When you provide confirmed drawings or validated samples, our manufacturing systems ensure every production unit matches your requirements exactly. This approach delivers the batch-to-batch consistency that makes fleet maintenance predictable and efficient.

Structural Consistency

Every unit performs identically under stress conditions

Interface Stability

Mounting points match specifications across all batches

Repeatable Production

Reliable supply for ongoing fleet programs

Scale-Ready Capacity

Manufacturing infrastructure for volume orders

Engineering Approach

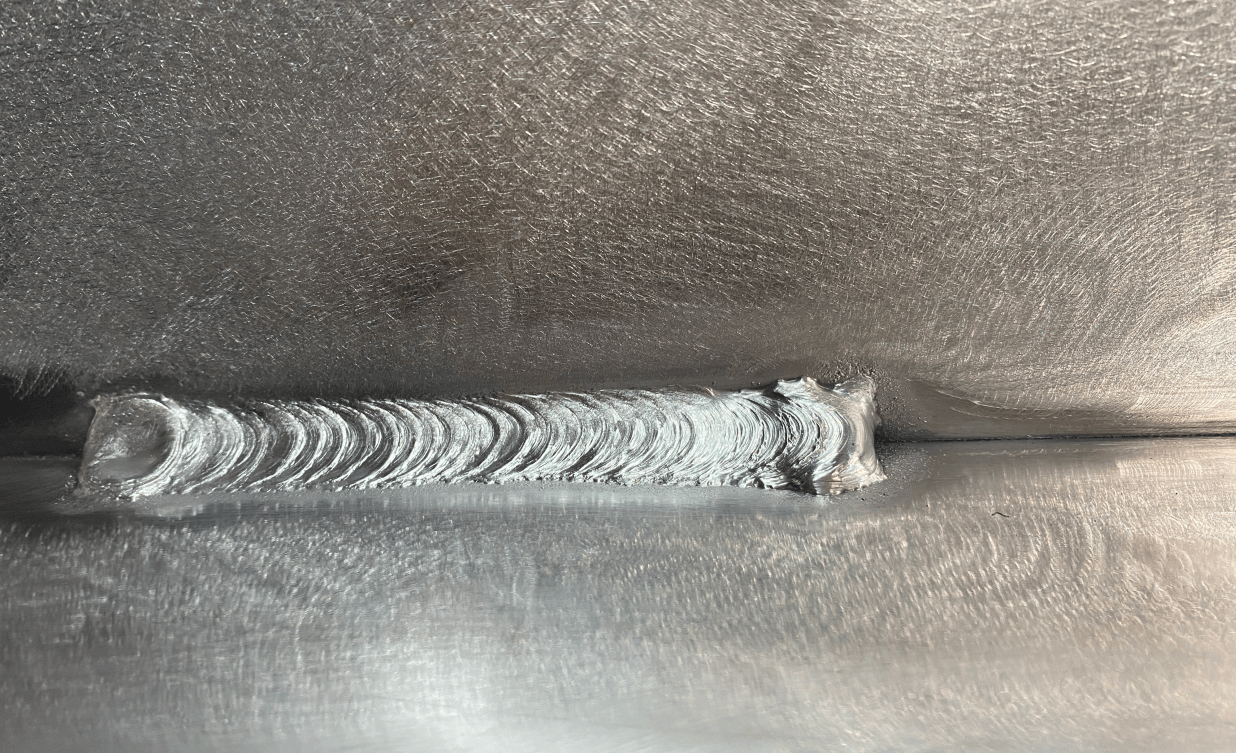

Material & Structure Built for Repairability

Our aluminum moose bumpers are engineered to manage impact energy while preserving repairability. The goal isn't invincibility—it's getting your trucks back on the road faster.

Aluminum Alloy Construction

Lightweight yet strong materials balance protection with fuel efficiency and reduce strain on front-end components during normal operation.

Impact Dispersion Design

Structural geometry distributes collision forces to minimize secondary damage to critical systems like cooling, lighting, and mounting structures.

Corrosion Resistance

Engineered to withstand road salt, moisture, and year-round exposure across diverse North American climate conditions.

Rapid Recovery Focus

Design philosophy prioritizes quick return to service after impacts, not zero-damage performance that compromises repair efficiency.

The Right Design Philosophy

Protection equipment that survives impacts without damage often transfers excessive force to mounting points and chassis components. Our approach accepts controlled bumper damage to protect what matters most: the truck's ability to return to service quickly.

Operational Impact

From Unpredictable to Manageable Downtime

Fleet operators report measurable improvements in maintenance predictability and operational stability when standardizing on consistent, quality-controlled protection systems.

Faster Repair Turnaround

Average repair time after wildlife impacts shows noticeable reduction when maintenance teams know exactly what to expect from consistent product construction.

Consistent Repair Processes

When every bumper behaves the same way after impact, technicians develop efficient repair workflows that apply across the entire fleet.

Simplified Parts Inventory

Standardized components across fleet vehicles enable advance stocking of replacement parts, eliminating procurement delays during critical repairs.

Seasonal Stability

High-risk wildlife seasons become manageable operational periods rather than unpredictable disruption events when protection systems perform predictably.

Ready to see how consistent manufacturing translates to operational benefits?

Discuss Your Fleet RequirementsBroader Application

Why This Case Matters Across Multiple Industries

The principles behind downtime reduction through consistent protection apply to diverse fleet operations facing similar operational challenges.

Logging & Northern Fleets

Remote routes through dense wildlife habitats create the highest collision frequency. Reliable protection directly impacts operational continuity in areas where roadside assistance is hours away.

Learn MoreLong-Haul Highway Fleets

Every hour of unplanned downtime carries the highest cost penalty. Consistent repair outcomes enable accurate scheduling adjustments and customer communication when incidents occur.

Learn MoreOEM & Fleet Programs

Large-scale standardization multiplies the value of consistent manufacturing. When hundreds of units perform identically, maintenance becomes a manageable system rather than individual problem-solving.

Learn MoreExplore all application scenarios to find what matches your operation.

View All ApplicationsFacing Similar Wildlife Collision & Downtime Challenges?

If predictable repair outcomes and consistent fleet maintenance matter to your operation, let's explore how our manufacturing approach applies to your specific requirements.

Talk to Our Engineering TeamNo forms required — direct conversation with our technical team