For your rig, OEM Heavy Truck Bumpers often strike the optimal balance between factory compliance, weight savings, and fuel efficiency, while aftermarket options provide superior impact protection for hazardous routes. Imagine cruising down a remote highway at 2 AM when a deer suddenly leaps into your path, shattering your plastic bumper and puncturing the radiator. That single impact creates thousands of dollars in towing fees, repair bills, and missed delivery deadlines. We leverage our expertise in oem aluminum bumpers for heavy truck manufacturing to help you avoid this costly downtime.

1. What Distinguishes Aftermarket From Factory Bumpers?

When you analyze the core differences, the distinction between aftermarket and factory bumpers comes down to their fundamental manufacturing intent. OEM aluminum bumpers for heavy truck applications are designed primarily for aerodynamics, fuel efficiency, and meeting minimum highway safety standards. They often utilize thinner stamped metals or plastic composites to keep vehicle weight down and production speeds high.

Conversely, aftermarket bumpers are engineered by specialized third-party manufacturers who focus on specific performance metrics like maximum impact resistance and off-road utility. These units prioritize the protection of vital engine components over mass-production cost savings. But here’s the kicker… the manufacturing process itself differs radically, shifting from high-speed injection molding to precision fabrication and casting.

Manufacturing Intent vs. Reality

Factory bumpers are built to be sacrificial parts that crumple to absorb energy during standard traffic accidents, potentially sacrificing themselves to save the frame. While this is effective for passenger safety in cars, it leaves heavy trucks vulnerable to disabling damage from minor animal strikes. Aftermarket engineers design their products to act as a shield, deflecting impacts to keep the truck operational.

- OEM focuses on crumple zones and pedestrian safety compliance.

- Aftermarket prioritizes radiator protection and animal strike deflection.

- Factory parts are optimized for low-cost mass production.

- Third-party options utilize heavy-gauge materials for longevity.

Material Thickness Differences

Standard factory bumpers often use materials that are just thick enough to hold their shape and support basic lights. In contrast, heavy-duty aftermarket options frequently employ 3/16-inch to 1/4-inch thick marine-grade aluminum or steel plate. This significant increase in material density provides the structural rigidity needed to push through snowdrifts or withstand brush impacts without deforming.

- OEM often uses <1/8 inch stamped steel or plastic.

- Aftermarket standardizes on >3/16 inch plate.

- Thicker material resists tearing and puncture.

- Structural integrity is maintained even after moderate impacts.

Crumple Zones vs. Impact Resistance

You might be wondering how this affects your safety in a crash. While OEM bumpers absorb energy by collapsing, heavy-duty aftermarket bumpers transmit more force to the mounts but prevent intrusion into the engine bay. The trade-off is between saving the bumper or saving the truck’s mechanical capability.

| Feature | OEM Bumpers | Aftermarket Bumpers | |

|---|---|---|---|

| Primary Goal | Compliance & Aerodynamics | Protection & Utility | |

| Material | Thin Steel/Plastic/Aluminum | Heavy-Gauge Aluminum/Steel | |

| Impact Strategy | Crumple & Absorb | Deflect & Shield | |

| Typical Weight | Light (<80 lbs) | Heavy (>150 lbs) or Light (Alum) |

The analysis shows that while OEM bumpers are designed to fail safely, aftermarket bumpers are designed to survive, making them the preferred choice for independent owner-operators who cannot afford downtime.

2. Do OEM Aluminum Bumpers for Heavy Truck Fit Best?

If your primary concern is a hassle-free installation that requires absolutely no modification to your rig, factory parts are usually the superior choice. OEM aluminum bumpers for heavy truck applications are engineered using the exact CAD data from the vehicle manufacturer, ensuring that every bolt hole, sensor mount, and bracket aligns perfectly with the frame rails. This precision eliminates the need for drilling, cutting, or wrestling with heavy components to get them to seat correctly.

For fleet managers who need to turn a repair around in a few hours to get a truck back on the road, this “plug-and-play” capability is a massive financial advantage. We adhere to these rigorous OEM-grade manufacturing standards to ensure seamless integration.

Precision Engineering Standards

Factory bumpers are produced with tolerances measured in millimeters, ensuring consistent gaps and body lines across thousands of units. This level of consistency is difficult for smaller aftermarket shops to replicate without advanced robotics. You might be wondering if aftermarket fitment is really that bad; the truth is, it varies wildly by brand.

- Factory parts guarantee consistent panel gaps.

- OEM alignment requires zero shimming or adjustment.

- Robotic welding ensures identical bracket placement.

- Installation manuals are standardized and validated.

Bolt-On Installation Ease

The beauty of an OEM replacement lies in the speed of the swap, which typically takes less than two hours with standard hand tools. Mechanics do not need to fabricate new mounts or relocate fluid reservoirs. This efficiency reduces labor costs significantly, making the total repair bill lower even if the part itself is pricey.

- No drilling into the frame rails is required.

- Existing hardware is often reusable.

- Electrical harnesses plug directly into stock connectors.

- One technician can often handle the job alone.

3D Scanning Technology

But here’s the kicker… top-tier aftermarket manufacturers have drastically narrowed the fitment gap by using 3D scanning technology. By mapping the front end of popular trucks digitally, they create bumpers that bolt on almost as easily as stock units. While you might still need to trim a plastic liner, modern aftermarket engineering is far superior to the “weld-it-yourself” kits of the past.

| Feature | OEM Bumpers | Aftermarket Bumpers | |

|---|---|---|---|

| Installation Time | 1-2 Hours | 2-5 Hours | |

| Modifications Needed | None (Direct Swap) | Minor drilling/trimming possible | |

| Sensor Alignment | Guaranteed Perfect | Brand Dependent | |

| Hardware Included | Reuses Factory | Heavy-Duty Hardware Provided |

The analysis confirms that OEM remains the king of fitment, but premium aftermarket brands are a viable alternative for those willing to invest slightly more labor for better protection.

3. Which Bumper Material Offers Superior Durability?

Durability is often the deciding factor for owner-operators who drive in areas with high wildlife activity or rough terrain. Stock bumpers are frequently referred to as “cosmetic” because they are made from thin stamped steel or plastic composites that offer little defense against anything harder than a big bug. You might be wondering why manufacturers would use such weak materials, and the answer is usually cost and weight reduction.

In contrast, aftermarket options are constructed to act as a shield for your truck’s vital components. High-quality aftermarket bumpers use marine-grade aluminum or heavy-gauge steel, often ranging from 3/16-inch to 1/4-inch thickness. This is significantly more robust than factory specifications.

Tensile Strength Comparisons

Aluminum alloys used in heavy-duty bumpers, such as 6061-T6, offer an incredible strength-to-weight ratio that rivals structural steel. This material allows the bumper to absorb massive amounts of energy without shattering like plastic or bending permanently like thin steel. It effectively dissipates the force of an impact across the entire structure.

- High-strength aluminum withstands significant force.

- Tensile yield strength exceeds standard mild steel.

- Material density prevents tearing upon impact.

- Structural shapes add rigidity without mass.

Impact Absorption Capabilities

Here is the deal: aluminum aftermarket bumpers are particularly impressive because they combine structural rigidity with a slight ability to flex. Under impact, they can deform elastically and return to their original shape, whereas steel might dent permanently. This “memory” effect can save the bumper during low-speed collisions that would otherwise require a replacement.

- Elastic deformation helps absorb shock.

- Prevents shock transfer to the frame rails.

- Reduces the likelihood of radiator puncture.

- Maintains structural integrity after minor hits.

Plastic vs. Metal Fatigue

Plastic bumpers become brittle over time due to UV exposure and temperature cycles, eventually cracking from minor vibrations. Metal bumpers, particularly aluminum, maintain their properties for decades. A fifteen-year-old aluminum bumper offers the same protection as the day it was installed.

| Material | Durability Rating | Impact Resistance | UV Resistance | |

|---|---|---|---|---|

| OEM Plastic | Low | Low (Shatters) | Poor (Brittle over time) | |

| OEM Steel | Medium | Medium (Dents) | High | |

| Aftermarket Aluminum | High | High (Flexes/Deflects) | Excellent | |

| Aftermarket Steel | Very High | Very High (Rigid) | High |

The analysis indicates that for long-term durability and impact survival, aftermarket aluminum significantly outperforms OEM plastic or thin steel options.

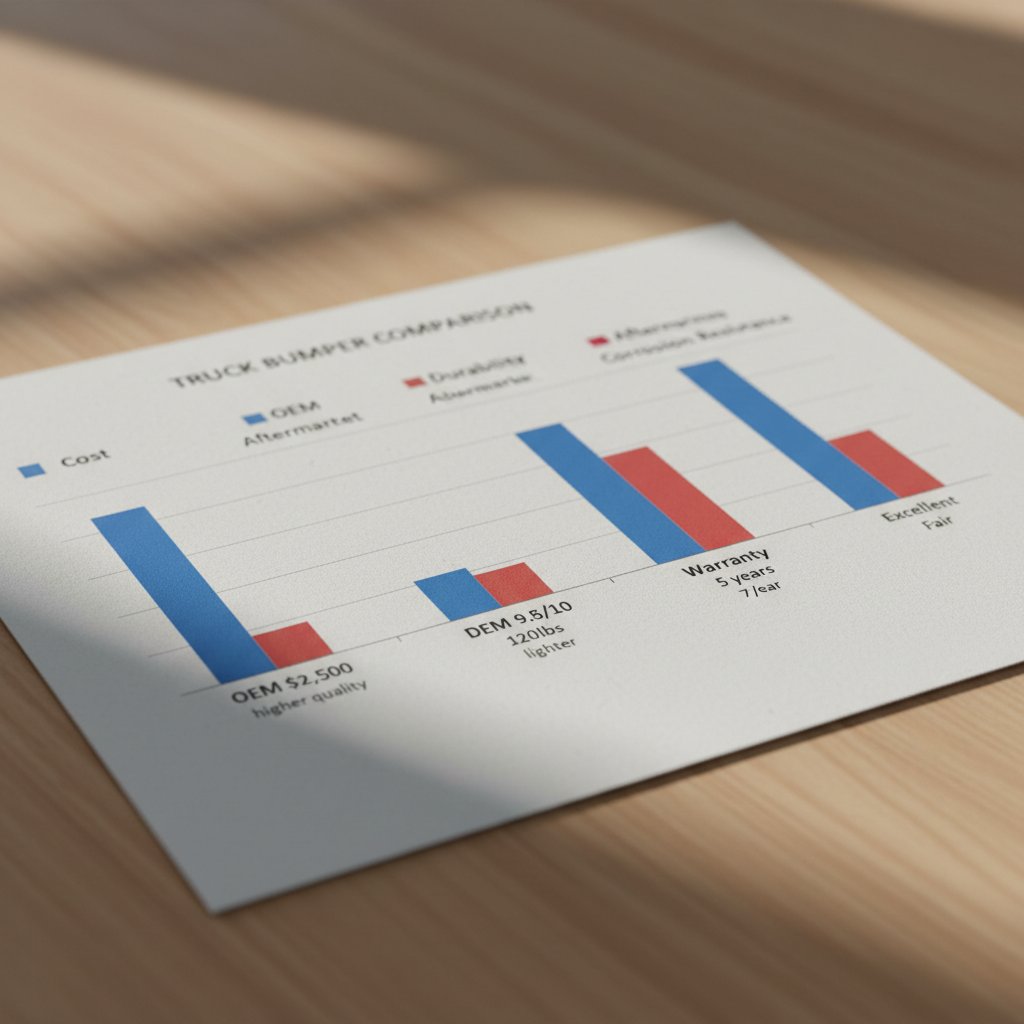

4. How Do Upfront Costs Compare to Long-Term Value?

When you look strictly at the price tag on the shelf, aftermarket bumpers often appear to be the more expensive option compared to standard OEM replacements. A heavy-duty aluminum herd bumper can cost significantly more than a simple factory plastic or chrome steel bumper. For a fleet manager looking at a spreadsheet, the OEM part looks like the logical choice to keep quarterly maintenance costs down.

However, this perspective ignores the hidden costs of durability and downtime. If you replace a cheap stock bumper three times over the life of the truck due to minor dings and cracks, you have already spent more than the cost of one robust aftermarket unit. What’s the real story? The true value lies in total cost of ownership.

Initial Purchase Price

Factory bumpers benefit from economies of scale, making their individual unit cost relatively low. Aftermarket bumpers are often hand-welded or cast in smaller batches, driving up the labor cost per unit. This initial sticker shock can be a barrier for small fleets.

- OEM plastic bumpers are the cheapest option.

- Aftermarket aluminum commands a premium price.

- Shipping costs for heavy bumpers add to the total.

- Installation labor can increase initial investment.

Downtime Cost Avoidance

If an aftermarket bumper prevents a radiator puncture during a low-speed collision, it has paid for itself instantly. You save the cost of a tow, a new radiator, and days of lost revenue while the truck sits in the shop. This “insurance policy” aspect is the primary financial driver for many owner-operators.

- Prevents radiator and intercooler damage.

- Eliminates towing bills for minor front-end hits.

- Keeps the truck generating revenue.

- Reduces insurance claim frequency.

Resale Value Retention

But here’s the kicker… aftermarket aluminum bumpers hold their resale value exceptionally well. You can often sell a used heavy-duty bumper for a decent price when you retire the truck, or transfer it to your new rig. A used stock bumper, especially one with road rash, is essentially scrap metal with zero recovery value.

| Cost Factor | OEM Bumper | Aftermarket Aluminum Bumper | |

|---|---|---|---|

| Initial Price | 500−1,500 | 1,800−4,500 | |

| Radiator Protection | Minimal | High | |

| Animal Strike Survival | Low | Very High | |

| Resale Value | Low | High (50-70% of new) |

The analysis proves that while aftermarket bumpers hurt the wallet more initially, they are the financially superior choice for any truck that faces real-world hazards.

5. Does Bumper Weight Impact Fuel Economy?

Weight is a critical enemy of efficiency in the trucking industry, and every pound you add to your rig affects your bottom line. Traditional steel aftermarket bumpers are notoriously heavy, sometimes adding 200 to 300 pounds to the front axle compared to a stock unit. This extra mass forces your suspension to work harder, accelerates tire wear, and can slightly reduce your fuel mileage.

For long-haul operations where fuel economy is tracked down to the decimal point, adding a massive steel slab to the front of the truck might cancel out the benefits of improved protection. Ready for the good part? This is where aluminum changes the equation entirely.

Axle Weight Ratings

An aluminum bumper can offer the same structural strength as a steel counterpart while weighing less than half as much. In many cases, a heavy-duty aluminum bumper weighs only slightly more than the flimsy stock bumper it replaces. This preserves your front axle weight rating for actual cargo.

- Maintains legal front axle weight limits.

- Allows for heavier payload capacity.

- Reduces stress on steer axle components.

- Prevents the need for heavier front springs.

Suspension Wear Analysis

Excessive weight on the front end acts as a lever, amplifying the stress on shocks, bushings, and kingpins. By choosing aluminum, you reduce this leverage effect, extending the life of your front suspension components. It essentially mimics the factory weight distribution while providing upgrade-level protection.

- Extends lifespan of shock absorbers.

- Reduces wear on steering linkages.

- Minimizes front-end dive during braking.

- Preserves factory ride quality.

Steel vs. Aluminum Mass

You might be wondering just how big the difference is. A full grille guard bumper in steel can weigh over 400 pounds, whereas the same design in aluminum might tip the scales at just 160 pounds. Over a year of driving, dragging that extra dead weight around costs real money in diesel fuel.

| Metric | Steel Aftermarket | Aluminum Aftermarket | OEM Stock | |

|---|---|---|---|---|

| Typical Weight | 250 – 450 lbs | 120 – 180 lbs | 60 – 100 lbs | |

| Fuel Impact | Negative | Neutral | Neutral | |

| Suspension Load | High | Low | Minimal | |

| Handling Effect | Heavy Steering | Stock Feel | Stock Feel |

The analysis clearly shows that aluminum aftermarket bumpers offer the protection of steel without the fuel and suspension penalties, making them the efficiency champion.

6. Can Aluminum Resist Corrosion Better Than Steel?

Driving through the Rust Belt or coastal regions exposes your rig to a constant barrage of salt, moisture, and chemical de-icers that eat away at metal. OEM steel bumpers, usually chrome-plated, are notorious for developing rust pits and peeling chrome after just a few winters. Once the protective layer is compromised by a stone chip, the steel underneath begins to oxidize rapidly.

Maintenance crews often waste hours polishing and treating these bumpers to keep them looking presentable. This is where it gets interesting… aluminum inherently solves this problem because it does not rust; instead, it forms a microscopic oxide layer that protects the metal.

Salt Spray Effects

Chemical de-icers like magnesium chloride are incredibly aggressive against steel, eating through even high-quality chrome plating. Aluminum is naturally resistant to these chemicals, making it the ideal material for trucks that operate in northern climates. It simply refuses to rot away.

- Immune to red rust and flaking.

- Resistant to magnesium chloride.

- Does not require constant waxing.

- Ideal for coastal and winter driving.

Self-Healing Oxide Layer

When aluminum is scratched, the exposed metal reacts with oxygen to form a hard, protective layer of aluminum oxide. This “self-healing” property prevents corrosion from spreading underneath the finish. Steel, by comparison, allows rust to creep under chrome or paint, causing it to bubble and peel.

- Scratches seal themselves naturally.

- Prevents “cancer” rust from spreading.

- Maintains structural integrity indefinitely.

- Requires no touch-up paint for protection.

Aesthetic Longevity

Here is the deal: for fleets that want to minimize shop time and keep trucks looking respectable, aluminum is an “install it and forget it” solution. Even an unpolished, raw aluminum bumper looks rugged and professional after years of abuse, whereas a rusty chrome bumper looks neglected.

| Environment | Steel Bumper Lifespan | Aluminum Bumper Lifespan | |

|---|---|---|---|

| Coastal/Marine | 3-5 Years | 10+ Years | |

| Winter/Road Salt | 4-6 Years | Indefinite | |

| Dry/Desert | 10+ Years | Indefinite | |

| Maintenance Need | High (Polishing/Waxing) | Low (Occasional Wash) |

The analysis confirms that aluminum is the superior choice for corrosion resistance, offering a lower maintenance burden and better long-term aesthetics.

7. Will Upgrades Void Your Manufacturer Warranty?

A common fear among truck owners is that bolting on an aftermarket part will instantly void the warranty they paid so much for. Dealers sometimes perpetuate this myth to discourage you from buying parts elsewhere. The reality is protected by federal law in the United States, specifically the Magnuson-Moss Warranty Act.

This legislation states that a manufacturer cannot void your entire warranty simply because you installed an aftermarket part; they must prove that the aftermarket part directly caused the failure. Here is the deal: you have rights that protect your ability to upgrade your rig.

Magnuson-Moss Warranty Act

This federal law prohibits manufacturers from conditioning their warranty on the use of branded parts. It puts the burden of proof on the dealer to demonstrate that your aftermarket bumper caused the specific failure in question. If your radio stops working, they can’t blame your bumper.

- Protects consumer choice in parts.

- Prevents blanket warranty voiding.

- Requires specific proof of causation.

- Applies to both parts and labor.

Burden of Proof Explanation

If you install a heavy bumper and your front suspension collapses, the dealer might have a case to deny that specific suspension claim. However, they cannot deny a warranty claim for your engine or transmission. It is a targeted exclusion, not a total loss of coverage.

- Dealer must prove the link.

- Warranty remains valid for unrelated parts.

- Documentation is key to disputes.

- Know your rights before visiting the dealer.

Component Coverage

You might be wondering how to stay safe. Sticking to reputable aftermarket brands that engineer their products to work within the truck’s specifications minimizes risk. Most high-quality aluminum bumpers utilize factory mounting points without altering the frame, which keeps you on safe ground regarding your chassis warranty coverage.

| Scenario | Warranty Status | Explanation | |

|---|---|---|---|

| Bumper Installation | Valid | Simply installing it does not void warranty. | |

| Engine Failure | Valid | Bumper has no effect on engine internals. | |

| Suspension Sag | At Risk | If bumper is overweight, claim may be denied. | |

| Sensor Malfunction | At Risk | If bumper blocks sensor, calibration is not covered. |

The analysis shows that while you need to be smart about weight, installing a quality aftermarket bumper is legally protected and generally safe for your warranty.

8. Do Aftermarket Bumpers Compromise Safety Sensors?

Modern heavy trucks are rolling computers, equipped with advanced driver assistance systems (ADAS) like collision mitigation radar and adaptive cruise control. These systems are calibrated to work through specific materials and at precise angles found on the stock bumper. A major concern is that installing a thick metal aftermarket bumper will block these signals.

Early aftermarket designs often failed this test, forcing drivers to choose between physical protection and electronic safety. But wait, there’s more… the leading manufacturers have now solved this engineering puzzle.