A Moose Bumper is the most effective way to safeguard your fleet against catastrophic wildlife collisions and expensive mechanical repairs. Imagine a late-night haul where a 1,500-pound animal suddenly crosses your path, leading to shattered radiators and sidelined drivers. This single event can wipe out your quarterly profit margins through repair costs and lost revenue. By installing structural protection from our Products collection, you turn a potential total-loss accident into a minor inconvenience that keeps your trucks on the move.

Why is a Moose Bumper essential for heavy trucks?

Reducing impact energy during collisions

Look at it this way: structural integrity is your first line of defense during a high-speed animal strike. High-tensile materials are engineered to absorb primary force, preventing it from reaching the chassis.

- High-tensile strength materials absorb the primary force.

- Deflects debris away from the engine block.

- Prevents structural frame twisting during off-center hits.

Protecting the radiator and cooling system

Think about this: a punctured radiator results in an immediate engine shutdown on the shoulder of a highway. Heavy-duty guards maintain the integrity of the Charge Air Cooler (CAC) and prevent fluid loss.

- Maintains the integrity of the CAC (Charge Air Cooler).

- Prevents immediate fluid loss that leads to engine overheating.

- Protects delicate cooling fins from smaller road debris.

Key Takeaway: The Value of Structural Defense

| Benefit | Impact on Operations | |

|---|---|---|

| Engine Protection | Eliminates catastrophic engine failure | |

| Driver Safety | Provides a physical buffer during impacts | |

| Longevity | Extends the life of OEM front-end parts |

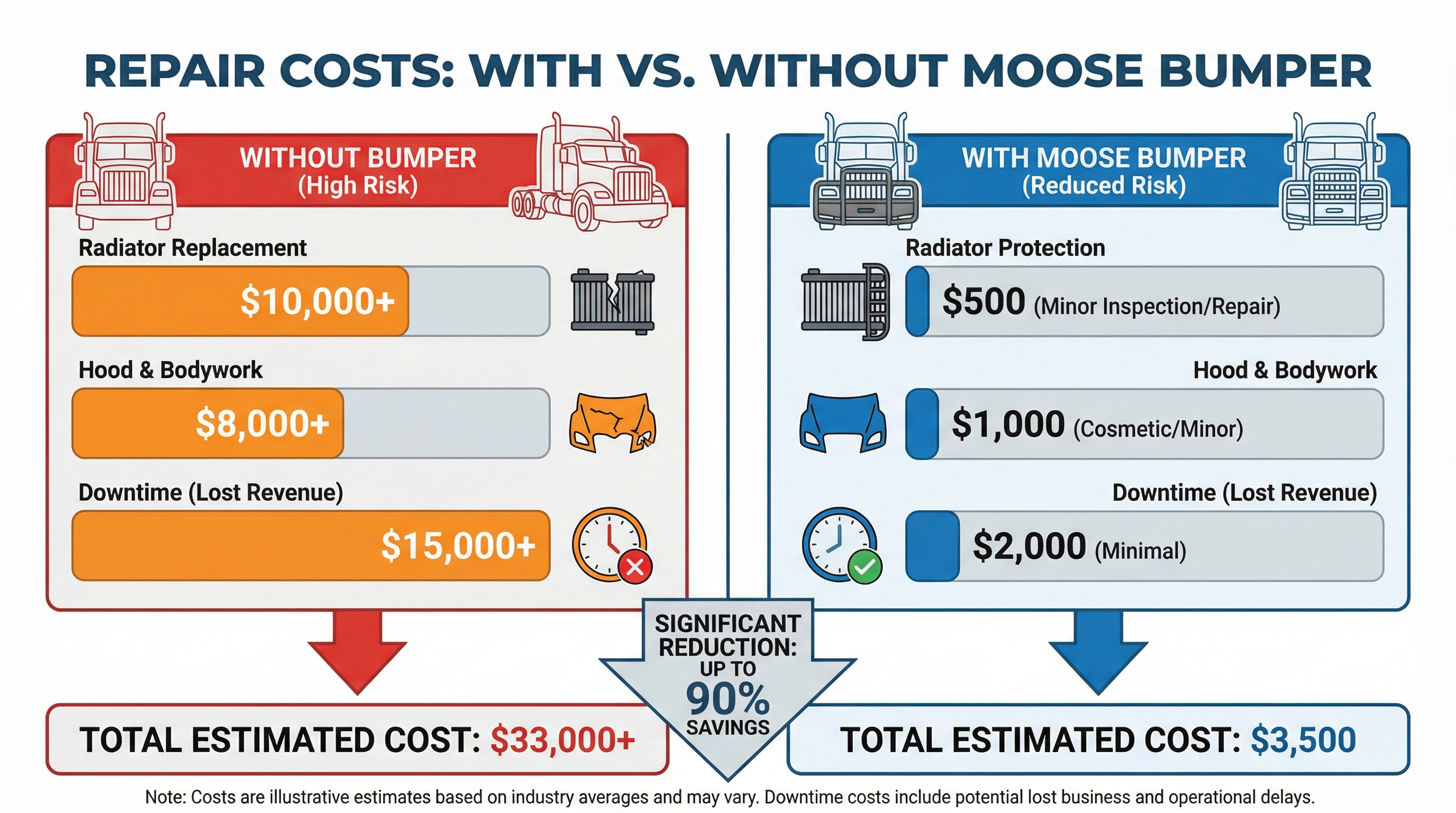

How much can a Moose Bumper save in repair costs?

Comparing repair bills with and without protection

Here is the kicker: the cost of a single hood and radiator replacement can exceed $20,000. Without a guard, you also face soaring insurance deductibles and potential premium hikes.

- Average cost of hood and radiator replacement vs. bumper cost.

- Impact on insurance deductibles and long-term premiums.

- Avoidance of emergency towing and roadside recovery fees.

Why downtime costs more than the Moose Bumper itself

The bottom line is: every day your truck sits in a repair shop, you are losing billable miles and revenue. Professional-grade protection ensures minor incidents don’t turn into two-week delays for specialized OEM parts.

- Avoiding the 2-4 week lead time for specialized OEM parts.

- Keeping delivery schedules intact despite minor incidents.

- Maintaining fleet reliability for high-priority clients.

Key Takeaway: Return on Investment (ROI)

| Financial Metric | Without Protection | With Moose Bumper | |

|---|---|---|---|

| Typical Repair Cost | 15,000−30,000 | 0−2,500 | |

| Days of Downtime | 14 – 21 Days | 0 – 2 Days | |

| Asset Value | Rapid Depreciation | Maintained Integrity |

What materials make the best Moose Bumper?

Evaluating aluminum vs. high-tensile steel

You might be wondering: which material provides the best balance of weight and strength for your specific route? While steel offers maximum impact resistance, aluminum preserves fuel efficiency for long-haul operations.

- Weighing the fuel efficiency of lightweight aluminum.

- Assessing the maximum impact resistance of structural steel.

- Understanding Grille Guard reinforcement patterns for added strength.

Which finish provides the best durability?

Wait, there’s more: the finish of your bumper is critical for resisting corrosion in harsh salt-belt environments. Powder coating provides a durable barrier, while polished finishes offer high visibility for brand aesthetics.

- Powder coating for superior corrosion resistance in salt-belt states.

- Polished finishes for high-visibility and professional brand appearance.

- Comparing these options to How to Upgrade OEM Aluminum Bumpers .

Key Takeaway: Material Selection

| Material Type | Pros | Best For | |

|---|---|---|---|

| Structural Steel | Highest impact rating | High-risk wildlife corridors | |

| High-Grade Aluminum | Lightweight, fuel-efficient | Weight-sensitive long haul | |

| Powder Coat | Rust prevention | Harsh winter environments |

Where can you install a Moose Bumper on fleet vehicles?

Compatibility with major truck brands

Simply put: a proper fit is essential for ensuring the guard functions as intended during an impact. Custom-fit designs are available for Freightliner, Kenworth, and Peterbilt to ensure a seamless bolt-on process.

- Custom-fit designs for Freightliner, Kenworth, and Peterbilt.

- Universal mounting systems for versatile fleet management.

- Integration with Pickup Guard systems for pilot cars.

Mounting options for maximum stability

Keep in mind: a bumper is only as reliable as the mounting points connecting it to the truck’s frame. High-quality systems use four-point mounting and include tilt mechanisms for easy engine access during maintenance.

- Four-point mounting systems for heavy-duty applications.

- Easy-tilt mechanisms for quick engine and radiator access.

- Direct bolt-on design that requires no frame modification.

Key Takeaway: Fitment and Accessibility

| Feature | Benefit | |

|---|---|---|

| Tilt Function | Seamless maintenance access | |

| Direct Bolt-On | No drilling or frame modification | |

| Custom Brackets | Maximum vibration resistance |

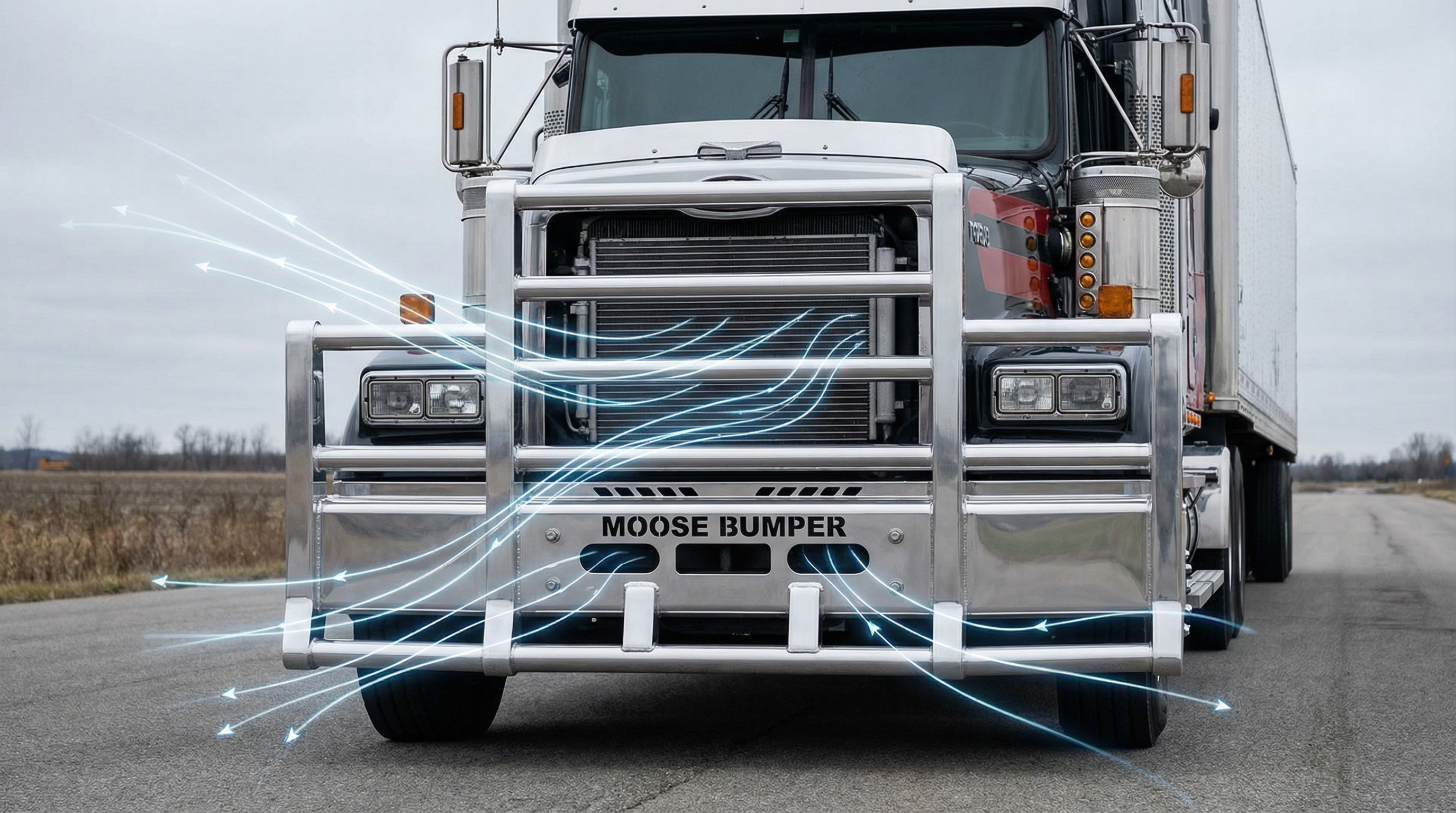

Which Moose Bumper design offers the best airflow?

Do vertical bars impact cooling efficiency?

The truth is: modern engine cooling requirements are more demanding than ever before. Choosing a design with an optimized open-air ratio ensures your engine receives enough air to prevent thermal derating.

- Calculating the open-air ratio of different bar patterns.

- Ensuring the engine receives adequate air for peak performance.

- Balancing protective coverage with necessary thermal management.

How aerodynamic designs improve fuel economy

Don’t miss this: safety upgrades should not come at the expense of your fuel mileage. Aerodynamic contours are designed to direct air around the cab, minimizing wind resistance at highway speeds.

- Low-profile designs that minimize wind resistance.

- Streamlined contours that direct air effectively around the cab.

- Reduced drag coefficients compared to traditional flat guards.

Key Takeaway: Efficiency and Airflow

| Design Element | Cooling Impact | Fuel Impact | |

|---|---|---|---|

| Slotted Vents | High airflow | Neutral | |

| Aero-Contouring | Moderate | 1-2% Improvement | |

| Wide Bar Spacing | Maximum Cooling | Minimal Drag |

Who should invest in a heavy-duty Moose Bumper?

Long-haul drivers in high-risk wildlife areas

Believe it or not: drivers operating in “Moose Alley” face statistically higher risks during night shifts. For these operators, a bumper provides psychological peace of mind on desolate, unlit northern roads.

- Identifying high-deer-density and moose-crossing routes.

- Why night-shift drivers face the highest statistical collision risk.

- Psychological benefits for drivers operating in remote areas.

Is it worth it for local deliveries?

Let’s face it: accidents aren’t limited to the open highway; urban hazards are equally costly. Guards protect against low-speed docking impacts and yard hazards while enhancing the truck’s resale value.

- Protection against low-speed docking impacts and yard hazards.

- Enhancing the long-term resale value of the power unit.

- Guarding against minor fender-benders in heavy traffic.

Key Takeaway: Target Applications

| Driver Profile | Risk Level | Recommendation | |

|---|---|---|---|

| Northern Long-Haul | Critical | Heavy-Duty Steel | |

| Regional Distribution | Moderate | Aluminum Guard | |

| Owner-Operator | High (Financial) | Full-Wrap Protection |

When is the best time to replace a Moose Bumper?

Signs of structural fatigue in your guard

It gets better: regular inspections can catch small issues before they lead to a total guard failure. You should look for hairline cracks in welds and any deformation in the mounting brackets.

- Inspecting for hairline cracks in welds after years of vibration.

- Checking for mounting bracket deformation or loose hardware.

- Reviewing OEM vs. Aftermarket Protection for better options.

Upgrading after a minor collision

Now, consider this: even a minor hit can compromise the structural integrity of the metal. A bent guard will no longer provide its rated protection during a subsequent, more severe impact.

- Why a bent guard no longer provides full rated protection.

- Utilizing insurance claims for a full bumper upgrade after hits.

- Replacing fatigued units to maintain fleet safety standards.

Key Takeaway: Maintenance and Lifecycle

| Indicator | Status | Action Required | |

|---|---|---|---|

| Visible Rust | Cosmetic/Surface | Refinish or Paint | |

| Bent Support | Structural Risk | Immediate Replacement | |

| Loose Mounts | Safety Hazard | Torque to Specs |

How does a Moose Bumper integrate with safety sensors?

Can collision avoidance tech still work?

Make no mistake: modern trucks rely heavily on radar-based braking and lane-departure cameras. It is vital to ensure that your bumper design doesn’t obstruct these critical safety systems.

- Ensuring radar-based braking systems remain unobstructed.

- Maintaining the line of sight for lane-departure cameras.

- Testing sensor sensitivity with heavy-duty metal guards.

Relocating radar and camera units

Here’s the deal: many manufacturers provide relocation kits to move sensors to a clear position on the bumper. This allows you to combine physical protection with the truck’s digital safety features seamlessly.

- Using factory-spec relocation kits for sensor integration.

- Calibrating electronics after a Moose Bumper installation.

- Ensuring adaptive cruise control functions without interference.

Key Takeaway: Tech Compatibility

| Sensor Type | Potential Conflict | Solution | |

|---|---|---|---|

| Adaptive Cruise | Signal blockage | Relocation Bracket | |

| Collision Mitigation | False positives | Specialized Cut-outs | |

| Fog Lights | Obstruction | Integrated Light Ports |

Why do insurance companies prefer a Moose Bumper?

That’s not all: insurers often view proactive safety equipment as a sign of a well-managed fleet. Equipping your trucks with animal guards can lower your “Loss Cost” profile and lead to premium incentives.

- Lowering the “Loss Cost” profile of your entire fleet.

- Incentives provided by insurers for proactive risk management.

- Demonstrating a commitment to driver and vehicle safety.

Lowering the risk of total-loss claims

As a matter of fact: a heavy-duty bumper can be the difference between a repairable fender-bender and a total-loss claim. By preventing engine damage, you reduce the complexity and cost of every insurance claim.

- Keeping minor hits from totaling the power unit.

- Reducing claim complexity by preventing engine component damage.

- Faster claim processing when structural damage is minimized.

Key Takeaway: Insurance Advantages

| Metric | Impact | |

|---|---|---|

| Claim Frequency | No change | |

| Claim Severity | Drastic Reduction | |

| Total Loss Risk | Minimized |

Where is the most reliable Moose Bumper manufactured?

Quality standards for North American roads

To put it simply: manufacturing location matters when it comes to material thickness and weld quality. Guards built for North American climates are better suited for extreme temperature variations and road salt exposure.

- Sourcing guards designed for extreme North American climates.

- Why localized manufacturing ensures better material thickness.

- Exploring essential Accessories for added utility.

How to verify manufacturing certifications

You see: not all steel or aluminum is created equal in terms of impact absorption. You should always check for ISO standards and reputable brand ratings within the professional trucking community.

- Checking for ISO standards and heavy-duty load ratings.

- Researching brand reputation and real-world performance reviews.

- Verifying the quality of TIG/MIG welding on main joints.

Key Takeaway: Quality Verification

| Standard | Importance | What to Look For | |

|---|---|---|---|

| Weld Quality | Structural Integrity | TIG/MIG consistency | |

| Steel Grade | Impact Absorption | ASTM Ratings | |

| Fitment Warranty | Long-term support | Manufacturer guarantee |

Frequently Asked Questions

Can I install a Moose Bumper myself?While many designs are bolt-on, the weight of these units often requires a shop lift or a two-person team. To learn more about our team and capabilities, visit our About Us page.

What’s the best Moose Bumper for a Freightliner Cascadia?For the Cascadia, an aerodynamic aluminum guard is usually the top choice to maintain fuel-efficiency ratings while providing protection. For specific fitment questions, please Contact our experts.

How do I know if my Moose Bumper is still effective after a hit?Inspect the mounting brackets and the main horizontal bars for permanent deformation or cracking. If the structure is compromised, you can find a replacement on our Home page.

Can I use a Moose Bumper with a tow hook?Most premium designs include “tow-through” features or quick-release pins to allow access to factory tow points. This ensures you never have to remove the guard for emergency recovery.

What’s the best way to clean a polished Moose Bumper?Use pH-neutral soap and a soft cloth to avoid scratching the surface. Regular maintenance and the right Accessories will keep your guard looking professional for years.