Heavy-Duty Chain Hangers for Real-World Load & Abuse

Built for heavy truck operations with zero tolerance for chain loss, frame damage, or roadside failure.

Why Chain Hangers Are Often Underestimated

Most buyers treat chain hangers as commodity items. This mindset leads to product failures, unexpected costs, and operational disruptions that could have been avoided.

Common Market Perception

-

"It's just a simple sheet metal box"

-

"It’s not a safety-critical component"

-

"Any product that fits is acceptable"

-

"Basic compliance is sufficient""

Real-World Operating Conditions

-

Carries hundreds of pounds of chain under dynamic impact

-

Endures constant high-speed vibration over thousands of miles

-

Exposed to rain, snow, road salt, mud, and debris year-round

-

Must maintain structural integrity under extreme temperature swings

"Chain hangers don't fail in catalogs — they fail on highways."

Stop treating chain hangers as afterthoughts. Discover the engineering difference.

Explore Our Engineering ApproachReal-World Usage Cases

From cross-country hauling to urban delivery, our chain hangers are engineered to perform in the toughest conditions.

Long-Haul Trucking

Securely mounting safety chains for cross-country freight. Must withstand constant vibration over thousands of miles.

Construction Equipment

Heavy-duty attachment points for towing machinery on jobsites. Handles extreme loads and rough terrain impacts.

RV & Trailer Towing

Reliable backup safety connections for recreational vehicles. Critical for family safety during highway travel.

Fleet Operations

Standardized mounting solution across hundreds of vehicles. Reduces maintenance complexity and inventory costs.

Whether you're managing a fleet, manufacturing trailers, or specifying components for OEM production, our chain hangers deliver consistent performance where it matters most.

Ready to discuss your specific application requirements?

Get Application ConsultationCommon Failure Modes That Cost You Money

Low-cost chain hangers often share these design and manufacturing shortcuts. Recognizing these patterns helps you avoid costly procurement mistakes.

Thin-Gauge Deformation

Using underspec material thickness saves cost initially but leads to bottom panel sagging and sidewall bowing under chain weight over time.

Weld Seam Cracking

Inconsistent or insufficient welding creates stress concentration points. Vibration cycles propagate cracks until complete joint failure occurs.

Drainage Design Failure

Without proper drainage, moisture and road chemicals accumulate inside, causing hidden corrosion before visible damage.

Mounting Hole Misalignment

Inaccurate hole positioning forces field modifications. Drilling new holes compromises frame integrity and creates installation liability issues.

Critical Insight

These issues rarely appear during initial inspection. They are design-stage shortcuts that surface later as downtime, rework, or liability.

Protect your fleet investment with properly engineered chain hangers.

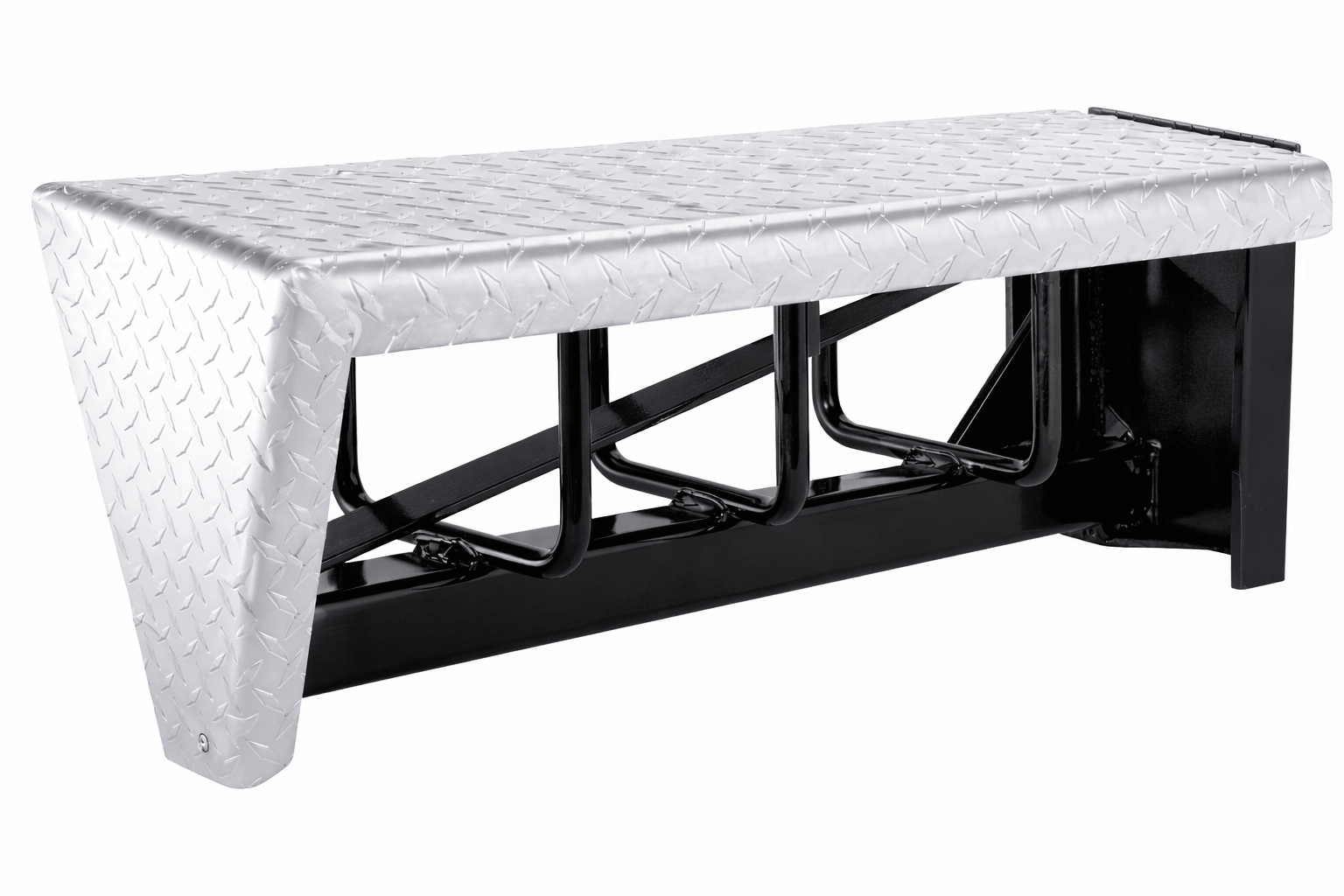

Request Quality AssessmentWhat Defines a True Heavy-Duty Chain Hanger

Move beyond subjective opinions. These four engineering criteria establish an objective framework for evaluating chain hanger quality.

Load-Bearing Structural Design

Manufactured as a structural component to distribute dynamic loads — not formed as a generic enclosure.

Material & Reinforcement

Material grades and reinforcement geometry verified against approved drawings.

Fatigue-Resistant Welding

Welds designed and executed for vibration fatigue resistance, not visual appearance.

Integrated Corrosion Control

Corrosion protection engineered into structure, drainage, and process — not added as paint.

Engineering-Based Evaluation Framework

These criteria transform subjective "good enough" assessments into objective engineering evaluations. When comparing suppliers, measure their products against these standards to identify true heavy-duty capability versus marketing claims.

Ready to specify chain hangers that meet real engineering standards?

Discuss Your RequirementsMaterial & Structural Manufacturing Logic

During manufacturing review, material grades, thickness, and structural features are verified against customer-approved samples or drawings.

Specified Material Implementation

Specified material grades and structural features are verified during manufacturing to meet load, fatigue, and durability requirements in approved drawings or samples.

-

Controlled Steel Grade Selection

Specified steel grades are sourced consistently to match approved material requirements.

-

Strategic Reinforcement Geometry

Reinforcement features specified in drawings or samples are consistently formed and positioned during manufacturing.

-

Optimized Wall Thickness

Material thickness is manufactured to match the values defined in approved specifications, not cost-driven minimums.

Load Path Verification

Manufactured structures follow the load paths defined in approved designs to distribute dynamic forces consistently.

Corner Reinforcement

High-stress corner areas specified in drawings are reinforced consistently during manufacturing.

Vibration Durability Control

Manufactured geometry and joints are verified to meet vibration durability requirements by the approved design.

Specified Weight Compliance

Material distribution and overall weight are controlled to match approved specifications without deviation.

Want to understand how our engineering approach differs from commodity suppliers?

Request Technical ConsultationWelding & Manufacturing Process

Every chain hanger undergoes a rigorous production process combining automated efficiency with skilled craftsmanship.

Precision Cutting

Laser and CNC cutting systems ensure consistent dimensions across production runs, eliminating variation in critical mounting points.

- ±0.5mm tolerance on hole centers

- Automated material handling

- Real-time quality verification

Robotic Welding

Computer-controlled MIG welding robots deliver consistent penetration and bead profiles on every unit, critical for load-bearing integrity.

- Uniform weld penetration

- Minimal heat distortion

- 100% traceability per batch

Surface Finishing

Multi-stage coating process protects against corrosion while maintaining dimensional accuracy required for precise installation.

- Pre-treatment cleaning

- Powder coat or E-coat options

- 1000+ hour salt spray resistance

"Our production combines robotic precision with manual quality verification. Every weld is inspected, every dimension checked before coating."

Want to discuss custom manufacturing specifications?

Request Technical ConsultationCorrosion Protection Is a System, Not a Coating

North American winters demand more than surface treatment. Our corrosion protection strategy addresses the complete lifecycle exposure environment.

Multi-Layer Protection System

Surface Preparation

Shot blasting removes mill scale and creates optimal surface profile

Chemical Pre-treatment

Phosphate conversion coating enhances adhesion and base protection

Primer Application

Epoxy primer provides barrier protection and corrosion inhibition

Topcoat Finish

Powder coat or E-coat provides UV resistance and appearance retention

Drainage Engineering

Specified drainage features prevent moisture accumulation inside

Beyond Surface Treatment

Most suppliers focus only on external appearance. Corrosion protection features specified in drawings or samples are implemented and verified during manufacturing.

- Interior cavity protection reaches hidden surfaces

- Weld seam coating prevents micro-crack corrosion entry

- Edge sealing eliminates bare metal exposure points

- Drainage holes positioned to evacuate trapped moisture

- Salt spray testing validates real-world performance

Key Insight

Corrosion protection = Design + Process, not just final paint. The most expensive coating fails if water can't escape from inside the structure.

Discuss coating options matched to your regional operating environment.

Get Coating RecommendationsWhy Precise Fitment Matters More Than You Think

Field modification increases labor cost, creates liability,compromises frame integrity.

Field Modification Risks

When mounting holes don't align, installers improvise. Each field modification introduces risks that compound over the product lifecycle.

- Drilling new holes weakens frame rails

- Elongated slots create loose mounting

- Installation labor costs increase 40-60%

- Warranty liability becomes unclear

Our Bolt-On Fitment Standard

We manufacture to vehicle-specific specifications with verified dimensional accuracy. Every hole pattern matches OEM mounting locations exactly.

- Vehicle-specific jig fixtures ensure repeatability

- CMM verification on critical dimensions

- Clear load path to frame mounting points

- Bolt-on installation with no modifications

Verify fitment compatibility for your specific vehicle applications.

Check Vehicle CompatibilityOEM & ODM Customization Capabilities

Whether you're a brand owner, distributor, or fleet operator, we provide the manufacturing flexibility to meet your specific product and branding requirements.

Dimensional Customization

Custom sizes, mounting configurations, and structural modifications to match your specific vehicle applications or product line requirements.

Brand Identity Integration

Logo embossing, custom labeling, branded packaging, and color matching to maintain your brand presence across the product experience.

Material Specification

Choice of steel grades, coating systems, and finish options to meet your target price point or performance specification requirements.

Product Line Matching

Coordination with your existing product range ensures visual consistency and cross-compatibility across your accessory lineup.

Full-Service OEM Partnership

From concept development to volume production, we support every stage of your product program.

Drawing Review

Engineering review of your specifications

Prototype Development

Sample production for fit and finish validation

Volume Production

Scalable manufacturing with consistency control

Logistics Support

Packaging and shipping to your specifications

Discuss your OEM/ODM requirements with our product development team.

Start OEM DiscussionQuality Control & Batch Consistency

Eliminate the "sample good, bulk bad" risk. Our quality system ensures every production run matches approved specifications with documented verification.

Sample Approval

First article inspection locks specification baseline.

Jig Fixture Setup

Dedicated tooling ensures identical production specs.

In-Process QC

Critical checkpoints catch deviations early.

Final Inspection

Complete verification before packaging shipment.

Specification Lock

Approved specs become locked parameters. No unauthorized changes.

Dimension Control

Mounting holes and weld locations verified every batch.

Weld Standards

Visual criteria applied consistently. No defects accepted.

Coating Verification

Film thickness and adhesion verified before shipment.

Request documentation of our quality control process and inspection standards.

Download QC DocumentationPackaging & Shipping: The Overlooked Last Mile

Products that survive manufacturing can still fail in transit. Our packaging engineering protects your investment from factory to final destination.

Protecting Your Investment in Transit

Chain hangers face unique shipping challenges. Heavy weight, rigid construction, and finished surfaces require purpose-designed packaging solutions.

- Individual unit separation with foam inserts prevents metal-to-metal contact

- Reinforced palletization withstands container stacking loads

- VCI protection or shrink wrap prevents moisture and rust formation

- Customized packaging options available for brand requirements

- Clear labeling and documentation for smooth customs clearance

Impact Protection

Multi-layer cushioning absorbs shocks from handling and transit vibration.

Surface Protection

Protective films prevent coating damage from friction during handling.

Load Optimization

Packaging maximizes container utilization while maintaining safety margins.

Documentation

Complete packing lists and shipping marks for smooth receiving process.

Discuss custom packaging requirements for your specific logistics needs.

Request Packaging SpecificationsBuilt for Professionals Who Demand Quality

Our chain hangers serve diverse customer segments across the heavy truck industry. Find your application and discover how we support your specific needs.

Fleet Operators

Consistent quality across all units reduces maintenance variance and procurement complexity.

- Bulk pricing programs

- Scheduled delivery planning

- Multi-vehicle compatibility

Parts Distributors

Reliable supply, competitive pricing, and products that minimize warranty returns.

- Distributor pricing tiers

- Drop-ship capability

- Marketing support materials

OEM & Private Label

Manufacturing partners who deliver consistent quality under your brand label.

- White-label manufacturing

- Custom branding options

- Confidential partnership

Truck Body Builders

Components that integrate seamlessly with assembly process. Zero production delays.

- Integration engineering

- JIT delivery options

- Technical support

Not sure which program fits your business? Let's discuss your specific requirements.

Find Your SolutionFrequently Asked Questions

Answers to the questions procurement professionals ask most often when evaluating chain hanger suppliers.

Yes. We support OEM programs starting from smaller MOQs for initial market testing, scaling to volume production as your program grows. Our flexible tooling approach keeps setup costs manageable for emerging brands and new product launches.

Absolutely. We accept customer drawings in all standard formats (DWG, DXF, STEP, PDF). Our engineering team reviews submissions for manufacturability and provides feedback on any recommended modifications before production begins.

Standard production lead time is 25-35 days from order confirmation, depending on quantity and customization requirements. Sample orders ship within 10-15 days. Rush production available for urgent requirements with advance arrangement.

Yes. We maintain dimensional databases for major truck models and can engineer mounting patterns to match existing OEM locations. If you have existing products to match, send samples or drawings and we'll ensure compatibility.

We offer powder coating (standard and premium grades), E-coat, zinc plating, and custom paint finishes. Color matching available for brand consistency. Our team can recommend the best coating system for your regional operating environment and price point.

We stand behind our products. Manufacturing defects are replaced at no charge. Our quality system minimizes claims, but when issues arise, we respond quickly with replacement parts or credit. Detailed warranty terms provided with quotation.

Still Have Questions?

Our team is ready to discuss your specific requirements and answer any questions not covered here.

Contact Our TeamReady to Source Quality Chain Hangers?

Whether you need a quick quote, technical consultation, or want to discuss a long-term OEM partnership, our team is ready to help.

Competitive Pricing

Factory-direct OEM pricing without middleman markups.

Engineering Support

Technical consultation included with every inquiry.

Sample Programs

Evaluation samples available before volume commitment.

Direct Contact

-

Email Us Brontectrailer@outlook.com

-

Response Time Within 24 Hours

Request a Quote

Fill out the form below and we'll get back to you promptly.