OEM Stainless Steel Grille Guards for Heavy-Duty Trucks

Built to customer drawings. Manufactured for North American fleets. Every grille guard meets exact vehicle specifications with consistent batch-to-batch quality.

A Grille Guard Is Not a Cosmetic Accessory

In real-world operating conditions, grille guards serve as critical structural components that protect valuable front-end systems and absorb impact forces throughout years of heavy use.

Front-End System Protection

Your grille guard shields headlights, radiators, intercoolers, and bumpers from direct impact damage. A single wildlife collision or debris strike can sideline a truck for days — the right grille guard prevents that downtime and the repair costs that come with it.

Load Transfer to Frame

Engineered mounting points distribute impact forces across the vehicle frame rather than concentrating stress at single points. This load distribution prevents localized structural damage and maintains the integrity of your truck's front-end architecture.

Long-Term Environmental Resistance

Heavy-duty trucks face road salt, gravel impacts, temperature cycling, and constant vibration every day. A properly manufactured grille guard withstands these conditions for years without structural degradation or surface failure.

The Bottom Line

A grille guard is structural protection equipment — not decoration. The difference between a grille guard that lasts and one that fails comes down to manufacturing quality, not design complexity.

Need grille guards built to handle real operating conditions?

Discuss Your RequirementsWhy Many Grille Guards Fail in Service

Most grille guard failures aren't design problems. They're manufacturing consistency problems that only show up after installation — or worse, after impact.

Weld Fatigue Cracking

Inconsistent weld penetration and improper heat control create stress concentrations. Cracks develop after months of road vibration, leading to sudden structural failure.

Mounting Hole Deviation

When mounting holes don't align with vehicle specs, installers drill new holes on-site. This weakens the mounting bracket and voids any structural integrity.

Surface Treatment Failure

Poor surface preparation or thin coatings lead to rust starting from the inside out. By the time it's visible, internal corrosion has already compromised structural strength.

Sample-to-Batch Variance

The sample looks perfect. But production batches use different materials, looser tolerances, or skip quality steps. You discover this when returns start arriving.

The Root Cause Is Manufacturing Consistency

Most failures trace back to production process variation — not product design. A factory that can't maintain batch-to-batch consistency will eventually ship you a problem, no matter how good the sample looked.

Looking for manufacturing consistency you can rely on?

Request Quality DocumentationStainless Steel Grille Guards Built for the Long Haul

Each grille guard is precision-manufactured using 304 stainless steel tubing and TIG welding, delivering the durability your fleet demands and the finish quality your brand deserves.

Most Coverage

Most Coverage

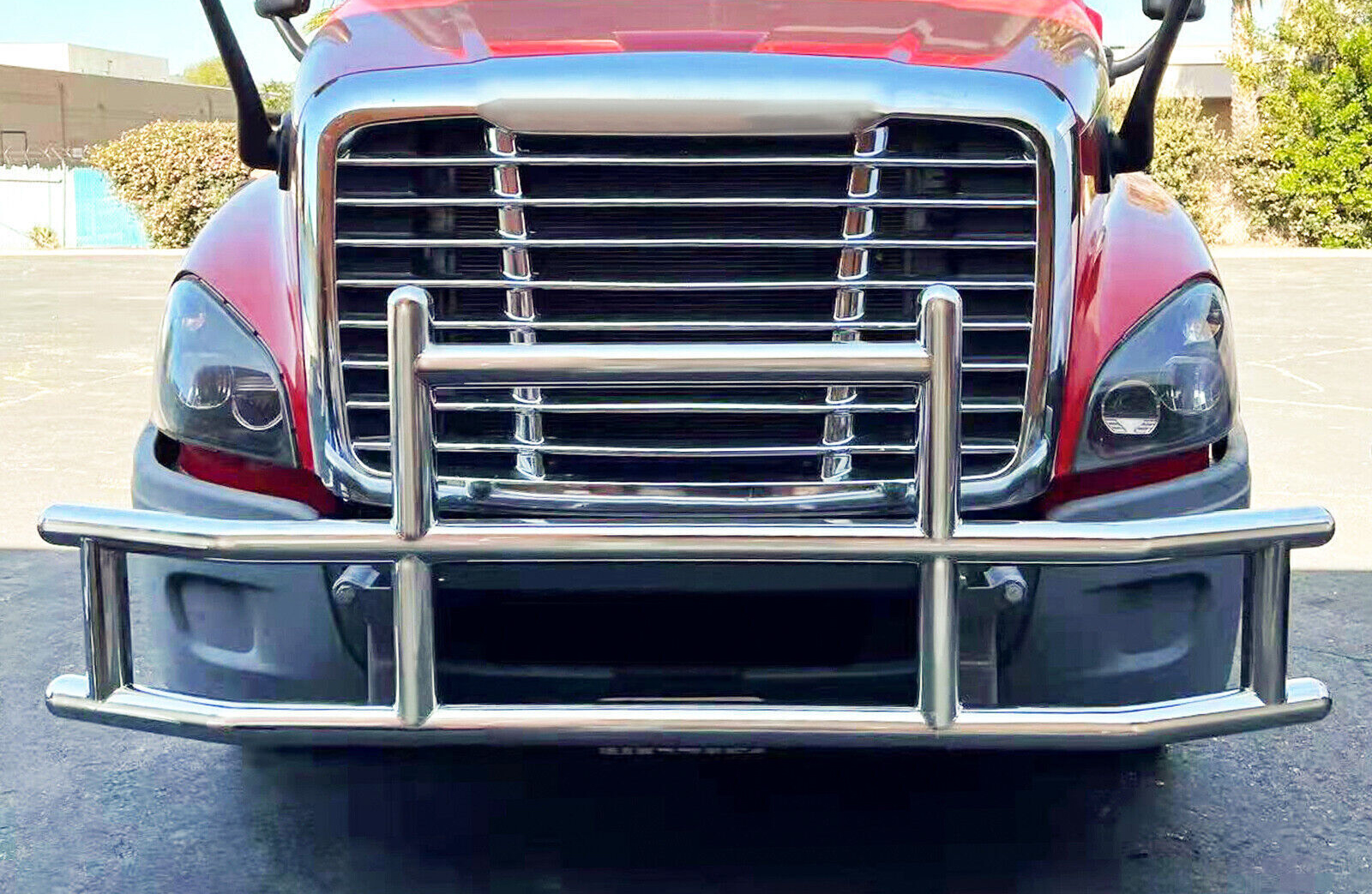

Full Front Protection Guard

Designed for fleets that require maximum front-end coverage. Protects the radiator, headlights, grille, and bumper systems from wildlife strikes, road debris, and daily highway impacts.

OEM Fit

OEM Fit

OEM Fit Grile Guard

Precision-engineered to align with factory frame mounting points. Eliminates field modifications, shortens installation time, and ensures consistent fit across fleet or OEM programs.

Severe Duty

Severe Duty

Heavy-Duty Impact Guard

Built with thicker-wall tubing and reinforced structural joints for severe-duty environments. Provides enhanced impact resistance for logging, oilfield, construction, and off-road operations.

Need a custom design for your specific truck model or fleet requirements?

Request Custom Quote4 Factors That Determine Grille Guard Service Life

When evaluating an OEM supplier, these manufacturing factors matter more than price. Each one directly impacts whether your product survives its intended service life.

Material Specification

Stainless steel grade, wall thickness, and material certification determine baseline strength and corrosion resistance for the product's entire service life.

Welding Process Control

Consistent weld parameters, proper fixtures, and qualified procedures ensure every joint meets strength requirements without hidden defects or stress concentrations.

Mounting Point Precision

Mounting holes and brackets must align perfectly with vehicle frame specifications. Tolerance stack-up errors make installation difficult and compromise load transfer.

Surface Protection System

Surface preparation, coating thickness, and cure parameters create the barrier against road salt, debris impact, and UV exposure that protects the underlying structure.

Ready to discuss manufacturing specifications for your grille guards?

Send Your Drawing for ReviewThree Finish Options for Every Application

Same heavy-duty stainless steel construction, different surface treatments. Choose the finish that matches your operating environment and brand identity.

Most Popular

Most Popular

Black Powder Coated

Industrial-grade powder coating over stainless steel base. Combines the durability of stainless with a low-profile matte black appearance that conceals road grime.

- Extra UV and scratch resistance

- Hides minor scratches and dirt

- Low maintenance requirements

Ideal For

Work trucks, construction sites, off-road applications where appearance is secondary to function

Premium

Premium

Polished Stainless

Mirror-finish polish that maximizes visual impact and reflects your commitment to quality. The ultimate choice for show trucks and premium fleet presentations.

- Mirror-like reflection

- Maximum visual impact

- Premium brand presentation

Ideal For

Show trucks, premium fleets, owner-operators who want to make a statement on the road

Flexible

Flexible

Custom Finish Options

Need something unique? We offer custom finish solutions tailored to your specific requirements. From custom colors to special coatings, we can match your fleet's brand identity.

- Custom powder coat colors

- Logo and branding options

- Specialty coatings available

Ideal For

OEM programs, branded fleets, and customers with specific visual or performance requirements

Same Structure. Same Protection. All finish options are built on identical heavy-duty stainless steel frames — only the surface treatment differs.

Not sure which finish fits your fleet? Let's discuss your requirements.

Request Finish SamplesOEM Cooperation Process

From initial drawings to batch delivery, every step is structured to eliminate uncertainty and ensure predictable outcomes for your supply chain.

Drawing Review

Submit your drawings or samples. We assess feasibility, material requirements, and production approach.

Process Confirmation

Align on manufacturing methods, quality checkpoints, and timeline. Create sample for your approval.

Pilot Batch

Small batch production validates consistency. You verify fitment and quality before full commitment.

Volume Production

Full-scale manufacturing with established quality controls. Same specs, every batch.

Packaging & Shipping

Protected packaging for ocean freight. Containerized for North American delivery.

No surprises. Every project follows this structured process. You know exactly what to expect at each stage, with clear communication throughout.

Ready to start the process with your grille guard project?

Submit Your DrawingsManufacturing & Quality Control

The biggest risk in OEM manufacturing is variance between samples and production batches. Our quality system is built specifically to eliminate that gap.

Critical Dimension Inspection

Mounting points and fitment dimensions are verified against customer specifications on every production batch. No assumptions, only measurements.

Weld Quality Verification

Welding parameters are controlled through fixtures and procedures. Visual and structural checks confirm joint integrity before products leave the line.

Surface Treatment Control

Coating thickness and adhesion are tested per batch. Surface preparation standards are documented and followed consistently across all production runs.

Process Documentation

Inspection records, material certificates, and production data are maintained for traceability. We provide documentation when you need it.

Sample = Production Batch

The most common complaint in OEM sourcing: the sample was perfect, but production batches weren't. Our entire quality system exists to ensure what you approve is what you receive — every time.

Want to discuss quality requirements for your project?

Request Quality DocumentationHow We Support Different Customers

Whether you're a brand owner, distributor, or fleet operator, we structure our partnership to match your specific business requirements.

For Brand Owners

Private Label Manufacturing

- Complete brand separation and confidentiality

- Dedicated production capacity for your orders

- Long-term supply agreements with price stability

For Distributors

Consistent Inventory Supply

- Multiple vehicle model coverage

- Scheduled shipments for inventory planning

- Flexible order quantities based on demand

For Fleet Operators

Fleet-Scale Solutions

- Batch consistency for uniform fleet appearance

- Fast installation reduces truck downtime

- Lifecycle cost focus over initial price

Which partnership model fits your business?

Discuss Your RequirementsPackaging & Delivery Built for Heavy-Duty Grille Guards

A grille guard manufactured perfectly but damaged in transit is a failed product. Our packaging is designed specifically for heavy components traveling long distances.

-

Reinforced Pallet Mounting

Grille guards secured directly on reinforced pallets designed to handle component weight and prevent shifting during transport.

-

Ocean Freight Stability

Load stability engineered for long-distance ocean shipping. Products arrive in the same condition they left the factory.

-

Surface Protection

Contact points wrapped and protected to prevent deformation and surface damage. No scratches, no dents on arrival.

-

Consistent Methods

Packaging methods are standardized across all production batches. What works for one shipment works for every shipment.

A grille guard that arrives damaged is a failed product — regardless of how well it was manufactured.

Have specific packaging or delivery requirements?

Confirm Packaging & Delivery RequirementsFrequently Asked Questions

Answers to the questions we hear most often from OEM buyers evaluating grille guard suppliers.

Have a question we didn't answer?

Contact Us DirectlyStart Your Project

Looking for a Stable OEM Supplier for Grille Guards?

Share your drawings or requirements — we'll review feasibility and provide a detailed quotation. Our team responds within 24 hours on business days.

- Free drawing review and feasibility assessment

- Detailed quotation within 48 hours

- No obligation — just straightforward answers

Email Us

Response Time

Within 24 Hours

Request OEM Quotation

Your information is secure. We never share your data with third parties.