Heavy-Duty Aluminum Moose Bumper

The Ultimate Fleet Protection

One unbendable moose bumper costs less than one accident. Protect your drivers, minimize downtime, and keep your fleet running with industrial-grade front-end protection engineered for North American highways.

Get Quote NowWhy North American Fleets Need Heavy-Duty Moose Bumpers

Standard OEM bumpers are not built for wildlife impacts or extreme highway conditions.The cost of inadequate protection extends far beyond replacement parts.

Wildlife Collision Risk

North American highways see over 1.5 million deer-vehicle collisions annually. Moose collisions cause severe damage and driver injuries.

OEM Bumper Failure

Factory-installed bumpers prioritize aesthetics over impact resistance. A single collision can disable a truck and put drivers at risk.

Costly Downtime

Every day your truck sits in the shop costs money. Fleet downtime after collision damage averages 5-10 days for major repairs.

Repair Expenses

Radiator, hood, engine compartment damage from frontal impacts often exceeds $25,000. Prevention costs a fraction of repair bills.

Don't wait for the next collision to protect your fleet investment.

Get Your Custom QuoteWhy Our Moose Bumper Protects Your Fleet

Every component is precision-engineered for maximum impact resistance while minimizing weight. Built to exceed the demands of long-haul trucking across North America.

6061-T6 Aluminum Alloy

Aircraft-grade aluminum delivers an exceptional strength-to-weight ratio. This advanced alloy maintains superior impact resistance while offering natural corrosion protection that outlasts steel alternatives in harsh road salt and weather conditions.

Reinforced Main Beam

Box-section main beam with internal gussets distributes impact forces across the entire frame structure. Engineered deflection zones protect the cab and driver while the bumper absorbs and redirects collision energy away from critical components.

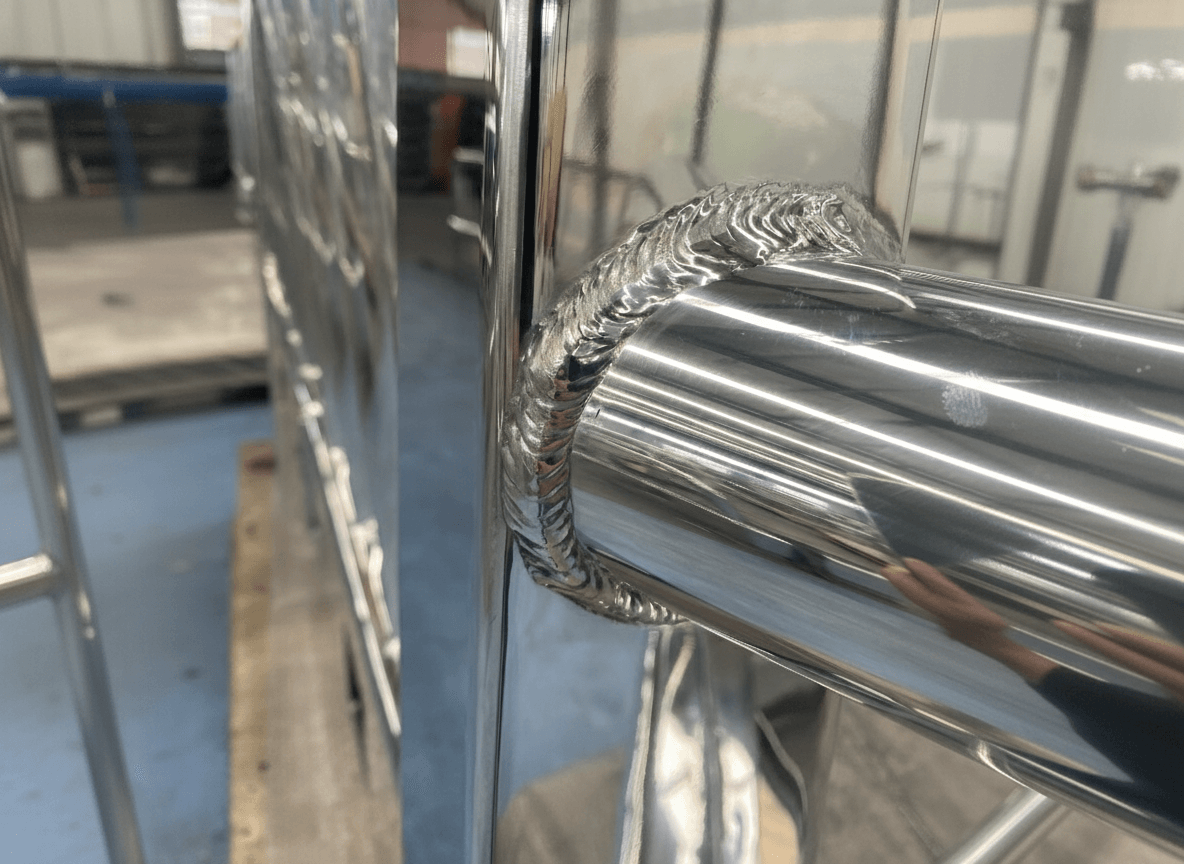

TIG / MIG Structural Welding

TIG and MIG welding processes are applied based on structural requirements and joint geometry. All welds undergo full visual and penetrant inspection to ensure strength, consistency, and reliability under extreme wildlife collision loads.

Structural-Grade Polishing

Controlled polishing ensures smooth weld transitions and uniform surface quality across the bumper. This reduces stress concentration at critical joints and supports long-term structural durability under heavy-duty impact conditions.

See the engineering that sets our bumpers apart from the competition.

Download Technical SpecificationsWhat Happens When a Collision Occurs?

The difference between standard OEM bumpers and heavy-duty Moose Bumpers becomes clear at the moment of impact. See why fleet operators are making the switch.

Without Moose Bumper Protection

A standard OEM bumper crumples on impact, allowing collision forces to transfer directly to the radiator, hood, and engine compartment. The result: extensive damage, weeks of downtime, and repair bills that can exceed the cost of the truck itself.

With Moose Bumper Protection

Our heavy-duty Moose Bumper absorbs and deflects impact forces away from critical components. The driver walks away uninjured, the truck sustains minimal damage, and your fleet is back on the road the next day.

Protect your fleet before the next collision. Request a sample and see the quality firsthand.

Request Product SampleWhy Aluminum Moose Bumpers Outperform Steel

Engineered for long-haul heavy trucks, our T6 aluminum moose bumpers deliver strong protection while reducing weight and supporting fuel efficiency.

T6 Aluminum Alloy

T6 Aluminum Alloy

Superior Strength-to-Weight Ratio

T6 aluminum delivers exceptional impact resistance at 40% less weight than steel. This translates to increased payload capacity and reduced strain on your front axle over long hauls.

Fuel Economy Benefits

Every 100 lbs saved equals approximately 1-2% fuel efficiency gain. Over 100,000+ miles annually, aluminum bumpers can save thousands in fuel costs for your fleet.

Natural Corrosion Resistance

Aluminum forms a protective oxide layer that resists rust and corrosion from road salt, rain, and harsh weather—maintaining appearance and structural integrity for years without extra coating.

Easy Repair & Replacement

Aluminum components can be welded, straightened, or replaced in the field more easily than steel. Minimize downtime and get your trucks back on the road faster after minor impacts.

Discover the long-term value of aluminum protection for your fleet.

Request Material SpecificationsCommon Industry Challenges—Solved

We understand the frustrations fleet managers face with overseas manufacturing. Our systematic approach eliminates the typical headaches that cost you time, money, and peace of mind.

Weld Cracks & Joint Failures

100% dual TIG/MIG welding process with certified welders. Every joint undergoes visual inspection and stress testing before shipping.

Hole Position Deviation

Laser-guided CNC positioning with ±0.5mm tolerance. Real vehicle fitment validation on sample units before mass production.

Unstable Lead Times

In-house production facility with dedicated capacity. OEM-level production management ensures 95%+ on-time delivery rate.

Shipping Damage

Secure pallet-based packaging with protective wrapping keeps bumpers stable and protected throughout long-distance shipping.

Stop settling for suppliers who don't understand your standards.

Discuss Your RequirementsOEM-Grade Manufacturing Capability

Trusted by leading North American brands, our facility delivers consistent, high-volume production with the precision and quality control that major OEMs demand.

Production Capabilities

- Built strictly to customer drawings and specifications

- 95% of production completed in-house for quality control

- CNC laser cutting with ±0.1mm precision

- TIG / MIG structural welding for load-bearing components

- Full in-house coating and polishing lines

- CMM inspection for dimensional accuracy

Customization Options

Partner with a factory that major brands already trust.

Explore OEM PartnershipThe 5 Priorities Every Fleet Buyer Demands

We've worked with hundreds of North American fleet managers and distributors. Here's what matters most—and exactly how we deliver on each point.

Consistent Quality

Multi-stage QC process with documented inspection reports. Every batch meets the same high standard—guaranteed.

Reliable Lead Times

Dedicated production capacity with real-time tracking. Know exactly when your order ships—no surprises.

Drawing Accuracy

Precision manufacturing to your exact specifications. CMM-verified dimensions with ±0.5mm tolerance.

Stable Supply

In-house factory with raw material inventory. Consistent availability even during peak demand seasons.

Fast Response

Dedicated account manager in your time zone. Quotes within 48 hours, questions answered same-day.

We understand what matters to your business—because we've listened.

Talk to Our TeamMoose Bumper Technical Specifications

Built to withstand the toughest conditions on North American highways. Every specification is engineered for maximum protection and durability.

Heavy-Duty Series

Heavy-Duty Series

Product Specifications

Compatible Vehicle Models

Need specifications for a specific vehicle model? We can help.

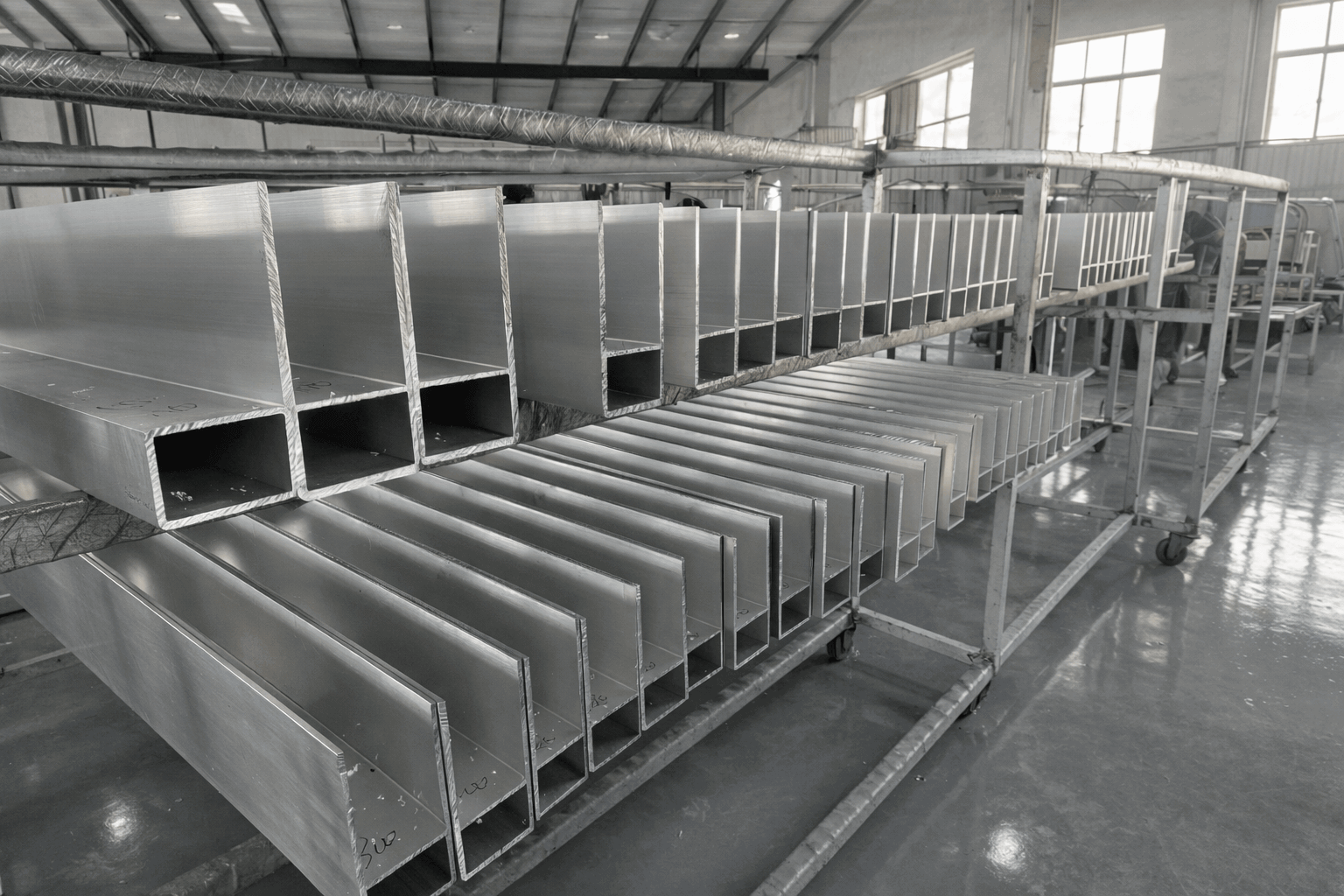

Download Full Spec Sheet Request Custom FitmentInside Our OEM-Grade Facility

Take a visual journey through our 50,000+ sqm production facility where precision engineering meets hands-on craftsmanship—not a trading company, but a real factory.

Tube Bending

CNC-controlled bending for precise structural tubes and frame-style moose bumper components.

CNC Laser Cutting

Fiber laser systems with ±0.1mm precision cutting accuracy.

Welding Station

AWS-certified welders with TIG/MIG dual process capability.

Surface Treatment

Full powder coating and polishing production line.

Quality Inspection

CMM measurement and multi-stage QC before shipment.

Container Loading

Custom steel frame packaging with drop-test certification.

Want to see our production process in action?

Request Virtual Factory TourWhat We Don’t Show — By Design

Certain information is never displayed or shared. This is how we protect our partners’ IP and competitive advantage.

Customer Technical Drawings

Your proprietary designs remain strictly confidential. We never share CAD files, specifications, or engineering details that could compromise your competitive advantage in the market.

Complete On-Truck Installations

Finished product photos could reveal your unique fitment solutions and branding. We protect our partners' market positioning by keeping their final applications private.

Internal Structure Details

Reinforcement patterns, mounting solutions, and structural innovations are protected IP. Competitors won't learn your design secrets through our marketing materials.

Frequently Asked Questions

Get answers to the most common questions about our moose bumpers, ordering process, and manufacturing capabilities.

Absolutely. We specialize in precision OEM manufacturing with ±0.5mm tolerance. Our process includes CAD file review, laser-guided CNC positioning, and CMM verification on all critical dimensions. We also perform real vehicle fitment validation on prototype units before mass production begins.

Our T6 aluminum moose bumpers typically weigh between 85-120 lbs depending on the model and configuration. This is approximately 40% lighter than equivalent steel bumpers, which helps improve fuel efficiency and increases payload capacity for your fleet.

Yes, we welcome trial orders to help you evaluate our quality before committing to larger volumes. We understand the importance of testing fitment and finish quality on your specific truck models. Contact us to discuss minimum quantities for your particular requirements.

We use laser-guided CNC positioning systems with ±0.5mm tolerance. All mounting points are verified using Coordinate Measuring Machine (CMM) inspection. For new designs, we perform actual vehicle fitment tests on prototype units to ensure perfect alignment before production.

Standard production lead time is 3-5 weeks depending on order quantity and customization requirements. We maintain dedicated production capacity for consistent scheduling. Ocean freight to North American ports typically adds 3-4 weeks. Expedited options are available for urgent orders.

Absolutely. We offer full OEM/ODM services including custom logo engraving, branded packaging, and private-label documentation. Many of our North American partners sell our products under their own brand names. We maintain strict confidentiality on all private-label projects.

Have a question that's not answered here?

Contact Our TeamGet In Touch

Get Your Moose Bumper Quote

Ready to upgrade your fleet's protection? Whether you need a quick quote, technical specifications, or want to discuss a custom OEM project, our team is ready to assist. Send us your requirements and we'll respond within 24 hours.

Request a Quote

Your information is secure. We never share your data with third parties.