Aftermarket aluminum bumpers generally offer superior durability and customization for working rigs compared to the standard fitment of OEM parts. You rely on your heavy-duty truck to handle the most demanding schedules and harshest environments, yet stock components frequently fail under pressure. Repairs lead to costly downtime that hurts your bottom line and disrupts your supply chain operations. Here is the deal: upgrading to robust protection ensures your fleet stays on the road while maintaining efficiency. This guide evaluates the trade-offs between factory options and specialized oem aluminum bumpers for heavy truck applications to help you make the right choice.

1. What Defines OEM vs. Aftermarket Specifications?

Original Equipment Manufacturer (OEM) specifications focus on aerodynamics and mass-production cost efficiency, whereas aftermarket specifications prioritize structural integrity and specific application needs. When you analyze oem aluminum bumpers for heavy truck data, you typically find thinner gauges of metal designed to meet minimum regulatory standards rather than maximum impact resistance.

You might be wondering, how substantial are the actual material differences between these two categories? Aftermarket engineers frequently utilize higher tensile strength alloys to combat the physical abuse that working trucks encounter daily.

How Do Material Grades Differ?

Factory bumpers often use standard stamped aluminum sheets that are lightweight but prone to tearing. But here is the kicker: specialized manufacturers use marine-grade or structural aluminum plate that can withstand significant force without deformation.

- Tensile Strength: Structural plate offers higher yield strength than stamped sheet.

- Thickness: Aftermarket plates are often double the thickness of OEM skins.

- Alloy Composition: Specialized alloys resist fatigue better than standard grades.

Key Takeaway

| Feature | OEM Specification | Aftermarket Specification | |

|---|---|---|---|

| Material Gauge | Thin Stamped Sheet (approx. 1/8″) | Structural Plate (approx. 1/4″ – 3/8″) | |

| Design Focus | Fuel Economy & Aerodynamics | Impact Protection & Utility | |

| Manufacturing | High-Volume Stamping | Precision Welding & Fabrication |

Analysis: While OEM specifications are adequate for highway cruising, aftermarket engineering provides the structural resilience required for vocational and severe-duty applications.

2. Do Factory Bumpers Offer Superior Fitment?

Factory bumpers guarantee a seamless installation because they are produced using the exact digital blueprints of the truck’s chassis. While oem aluminum bumpers for heavy truck units drop directly onto the frame rails without adjustment, leading aftermarket brands have closed this gap using advanced 3D scanning technology.

Ready for the good part? You no longer have to sacrifice precision fitment to get the heavy-duty protection your rig needs.

Is Installation Easier With OEM?

OEM parts align perfectly with every bolt hole and bracket on the assembly line. It gets better, however, as modern aftermarket kits now include adjustable mounts that compensate for minor frame variances common in older trucks.

- Alignment: OEM is fixed; aftermarket often allows for fine-tuning.

- Hardware: Aftermarket kits usually upgrade mounting bolts to Grade 8.

- Time: OEM installs are faster; aftermarket may take 1-2 extra hours.

Key Takeaway

| Fitment Aspect | OEM Bumper | Brontec/Aftermarket Bumper | |

|---|---|---|---|

| Bolt Pattern | Exact Match | Precision Match/Adjustable | |

| Modification | None Required | Rarely Required | |

| Labor Time | 1 Hour | 2-3 Hours |

Analysis: Although OEM offers the fastest install, the adjustable nature of high-quality aftermarket systems ensures a tighter, more secure fit on working trucks that may have slight frame flex.

3. Are Aftermarket Aluminum Bumpers More Durable?

Aftermarket aluminum bumpers significantly outperform factory units in durability due to their welded internal substructures and thicker faceplates. While an OEM bumper often crumbles to absorb energy in minor incidents, robust grille guards and bumpers are engineered to deflect impacts and keep the truck operational.

This is where it gets interesting for fleet managers calculating long-term repair costs. A bumper that survives a low-speed collision without needing replacement pays for itself immediately.

Can They Withstand Wildlife Strikes?

Structural aluminum bumpers are specifically designed to push deer or debris down and away from the wheels. What is the real story? An OEM bumper will likely fold into the radiator, causing expensive engine damage, while a reinforced bumper protects these critical components.

- Deflection: Angled plates redirect impact energy.

- Protection: Grille tubes guard the radiator and intercooler.

- Resilience: Welded seams hold together better than rivets.

Key Takeaway

| Durability Factor | OEM Standard | Aftermarket Heavy-Duty | |

|---|---|---|---|

| Impact Type | Energy Absorption (Crumple) | Deflection & Resistance | |

| Animal Strike | Likely Radiator Damage | Minimal Cosmetic Damage | |

| Structural Life | 5-7 Years | 10+ Years (Lifetime Potential) |

Analysis: The primary value of an aftermarket upgrade lies in its ability to convert a potentially catastrophic front-end collision into a non-event that requires zero downtime.

4. Which Option Provides Better Cost Efficiency?

Aftermarket bumpers frequently offer better long-term cost efficiency despite a potentially higher initial price tag. Purchasing oem aluminum bumpers for heavy truck replacements repeatedly after minor accidents accumulates costs rapidly, whereas a single investment in a heavy-duty guard serves for the life of the vehicle.

Let’s face it, the sticker price is only one part of the financial equation for a commercial vehicle.

Is the Upfront Cost Justified?

Spending more initially prevents thousands of dollars in hood, light, and cooling system repairs later. Here is the bottom line: insurance deductibles and downtime from a single accident often exceed the price difference between OEM and premium aftermarket protection.

- Replacement Frequency: High for OEM; Low for Aftermarket.

- Asset Protection: Aftermarket guards protect expensive hoods.

- Resale Value: Upgraded protection adds value at trade-in.

Key Takeaway

| Cost Component | OEM Bumper | Aftermarket Bumper | |

|---|---|---|---|

| Purchase Price | High ($$$) | Variable ($$-$$$$) | |

| Repair Liability | High (Exposed Parts) | Low (Shielded Parts) | |

| ROI Timeline | Immediate (Cheaper) | 1-2 Years (Savings) |

Analysis: While the initial cash outlay for aftermarket is higher, the total cost of ownership is lower when factoring in avoided repairs and reduced operational downtime.

5. How Does Weight Impact Truck Performance?

Excessive weight on the front axle accelerates tire wear and alters steering geometry, making aluminum the superior material choice over steel. Using advanced engineering, aftermarket manufacturers create bumpers that are stronger than OEM without adding the substantial weight penalty associated with steel replacements.

Why does this matter? You maintain your payload capacity and fuel efficiency while gaining the protection you need.

Does Lighter Mean Weaker?

Modern engineering proves that structural stiffness comes from geometry, not just mass. You might be surprised to learn that a well-designed aluminum box structure can equal the impact resistance of steel at less than half the weight.

- Fuel Economy: Lighter front end improves MPG.

- Suspension Life: Reduced stress on shocks and bushings.

- Steering: Sharper response with less front-axle mass.

Key Takeaway

| Material Option | Weight Impact | Strength-to-Weight Ratio | |

|---|---|---|---|

| OEM Aluminum | Very Light | Low | |

| Aftermarket Aluminum | Light | High | |

| Aftermarket Steel | Heavy (+150lbs) | Moderate |

Analysis: Aftermarket aluminum strikes the perfect balance, offering the protective benefits of heavy armor without the mechanical penalties of adding massive weight to the front axle.

6. Can You Customize OEM Truck Bumpers?

OEM bumpers are mass-produced with limited options, typically offering only standard fog light cutouts and a license plate mount. Conversely, custom design configurations rarely support the specialized equipment required for logging, heavy haul, or night operations.

Check this out: aftermarket solutions essentially act as a utility platform for your specific work requirements.

What Accessories Can Be Integrated?

Aftermarket designs allow for the seamless integration of high-output lighting, winches, and oversized load signage. It gets better, as these features are built directly into the structure rather than bolted on as flimsy afterthoughts.

- Lighting: LED light bars and spot pods.

- Recovery: 15,000lb+ winch trays and tow hooks.

- Utility: Steps for engine access and flag mounts.

Key Takeaway

| Customization | OEM Standard | Aftermarket Custom | |

|---|---|---|---|

| Auxiliary Lights | Factory Locations Only | Unlimited Configurations | |

| Winch Mount | Not Available | Integrated Tray | |

| Finish Options | Chrome/Paint | Polish/Powder/Line-X |

Analysis: For drivers who treat their truck as a mobile office and toolbox, aftermarket bumpers provide the necessary mounting real estate for critical operational gear.

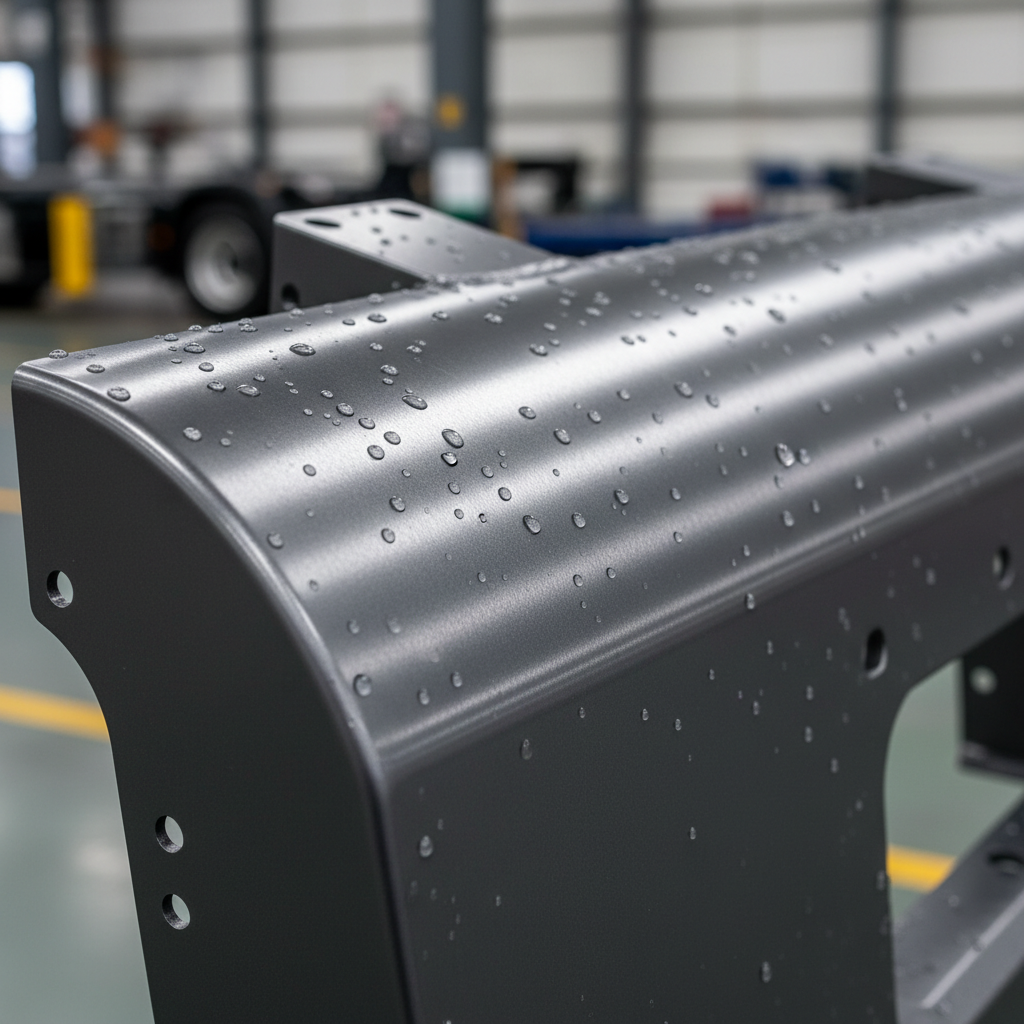

7. Does Corrosion Resistance Vary by Manufacturer?

Corrosion resistance is inherent to aluminum, but the quality of the finish and the mounting hardware determines the longevity of the assembly. While oem aluminum bumpers for heavy truck units are resistant, they often pair aluminum skins with mild steel brackets that rust and fail prematurely.

Here is the secret: premium aftermarket manufacturers use aluminum substructures or galvanized brackets to ensure the mounting system lasts as long as the bumper itself.

How Does Finish Affect Longevity?

A polished mirror finish is easier to maintain on aftermarket accessories than the thin chrome plating found on some OEM parts. You need to know that once OEM chrome peels, corrosion spreads quickly, whereas raw aluminum can simply be re-polished.

- Oxidation: Aluminum creates a protective oxide layer.

- Maintenance: Polish maintains shine; coating prevents pitting.

- Galvanic Reaction: Isolation pads prevent steel-aluminum corrosion.

Key Takeaway

| Component | OEM Corrosion Risk | Aftermarket Corrosion Risk | |

|---|---|---|---|

| Bumper Face | Low (Aluminum) | Low (Aluminum) | |

| Brackets | High (Painted Steel) | Low (Galvanized/Aluminum) | |

| Finish Durability | Moderate (Peeling) | High (Polishable) |

Analysis: The weak link in OEM corrosion resistance is often the mounting hardware, a problem that high-end aftermarket suppliers solve through better material selection.

8. How Does Plaster Casting Affect Quality?

Plaster casting is a specialized manufacturing method used to create intricate aluminum parts with superior surface finishes, though it is less common for main structural bumper beams. While oem aluminum bumpers for heavy truck main bars are typically stamped or extruded, plaster casting is sometimes utilized for complex trim pieces, light housings, or prototypes where detail is paramount.

You might be wondering, why talk about casting if most bumpers are plate? Understanding the difference helps you identify quality manufacturing in the small details that separate a premium product from a basic one.

Is Plaster Casting Common for Bumpers?

It is reserved for components requiring tight tolerances and smooth surfaces that machining cannot easily achieve. But here is the kicker: while not used for the impact zone, cast aluminum components in an aftermarket assembly often indicate a high-end product where aesthetics and design freedom were prioritized.

- Detailing: Allows for complex curves and logo embossing.

- Finish: Produces a surface smoother than sand casting.

- Usage: Trim, bezels, and non-structural aesthetic elements.

Key Takeaway

| Method | Application | Benefit | |

|---|---|---|---|

| Plate Fabrication | Main Impact Structure | Maximum Strength | |

| Plaster Casting | Decorative/Complex Trim | Superior Finish/Detail | |

| Stamping | OEM Mass Production | Low Cost/Volume |

Analysis: While the brute strength of a bumper comes from fabricated plate, the presence of plaster-cast details often signals a premium aftermarket product designed with aesthetics in mind.

9. Do Warranties Cover Aftermarket Modifications?

Aftermarket warranties often exceed factory coverage regarding structural integrity, though you must navigate the nuances of your vehicle’s original warranty. oem aluminum bumpers for heavy truck parts are covered under the truck’s general warranty, but reputable aftermarket brands frequently offer lifetime guarantees against breakage.

Don’t worry, the Magnuson-Moss Warranty Act protects your right to install aftermarket parts without automatically voiding your truck’s manufacturer warranty.

Will You Void Your Factory Warranty?

Dealers cannot deny a warranty claim unless they prove the aftermarket part caused the specific failure. Ready for the good part? This means you can upgrade your protection without fear, provided you choose high-quality components that do not interfere with airflow or sensors.

- Structure: Aftermarket often has Lifetime coverage.

- Finish: Typically 1-3 years for powder coat/polish.

- Compliance: DOT-compliant parts are safe to install.

Key Takeaway

| Warranty Type | OEM Coverage | Aftermarket Coverage | |

|---|---|---|---|

| Structural Defects | 1-3 Years | Lifetime (Common) | |

| Workmanship | Limited | Lifetime | |

| Impact Damage | Not Covered | Sometimes Covered |

Analysis: Aftermarket manufacturers stand behind their products with stronger warranties because their components are over-engineered compared to the disposable nature of OEM parts.

10. Is Safety Compromised With Aftermarket Parts?

Modern aftermarket bumpers are rigorously engineered to maintain the functionality of Advanced Driver Assistance Systems (ADAS) and crash safety features. While oem aluminum bumpers for heavy truck designs integrate radar and sensors natively, leading aftermarket brands now include precise cutouts and mounting points to relocate these sensors without calibration issues.

Safety first is the rule, and a heavier bumper must not impede the deployment of airbags or the operation of collision avoidance systems.

Do Sensors Work Through Thicker Metal?

Engineers design specific windows or relocation brackets to ensure radar waves are not blocked by the thicker aluminum plate. Here is the deal: provided you buy from a reputable manufacturer, your collision mitigation system will function exactly as intended.

- Radar: Relocation kits maintain sensor field of view.

- Airbags: Mounting brackets are tuned to transmit impact pulse.

- Testing: Quality brands simulate sensor performance.

Key Takeaway

| Safety Feature | OEM Integration | Aftermarket Integration | |

|---|---|---|---|

| Radar/CMS | Native | Relocated/Compatible | |

| Parking Sensors | Native | Pre-Cut Holes | |

| Crumple Zones | Active | Compatible/Reinforced |

Analysis: You do not have to choose between advanced safety electronics and physical protection; modern aftermarket engineering successfully merges both.

Conclusion

Choosing between OEM and aftermarket protection ultimately depends on your operational priorities. If you require a standard restoration with zero modification, OEM is a safe bet, but for fleets demanding extended durability, lower lifecycle costs, and enhanced utility, aftermarket aluminum is the superior investment. Brontec specializes in delivering engineering-grade solutions that solve the fragility issues of stock components. Contact us today to secure your fleet with protection that pays for itself.

FAQ

Q1: Will installing an aftermarket bumper make my truck too heavy?No, provided you choose an aluminum aftermarket bumper. While they are stronger than stock, aluminum designs are significantly lighter than steel alternatives and often weigh only slightly more than OEM parts, having negligible impact on your suspension or fuel economy.

Q2: Can I repair an aluminum bumper if it gets dented?Yes, unlike plastic or thin stamped steel which often must be replaced, heavy-duty aluminum plate can often be welded, straightened, and polished back to a near-new condition. This repairability is a major factor in reducing long-term maintenance costs for fleets.

Q3: Do aftermarket bumpers interfere with my collision avoidance system?No, high-quality aftermarket bumpers are designed with specific ports and brackets to accommodate factory radar and parking sensors. Always verify that the specific model you are purchasing is rated as “sensor compatible” for your truck’s make and year.

Q4: Is the “marine-grade” aluminum really different from standard aluminum?Yes, marine-grade aluminum (typically 5xxx or 6xxx series) contains magnesium and silicon, offering far superior resistance to corrosion and stress cracking compared to standard commercial grades. This is essential for trucks operating in winter conditions with road salts.

Q5: Why is plaster casting mentioned in relation to bumpers?Plaster casting is a manufacturing technique used to create highly detailed aluminum parts with smooth finishes. While the main structural bars of a bumper are fabricated from plate, plaster casting is sometimes used for intricate trim pieces, light bezels, or branding elements to give a premium aesthetic.